Battersea Power Station was a landmark beloved of the public even before it appeared on the cover of Pink Floyd’s Animals album. So the pressure was on when Historic England insisted on replacing the four iconic chimneys with perfect replicas of the originals

‘We’ve used 6,174 wheelbarrow-loads of concrete to build this chimney,” Gary Spooner shouts, trying to make himself heard in the gusting wind that heralds the approach of storm Barney. As construction manager for enabling works contractor Skanska on Phase 2 of the Battersea Power Station redevelopment, Spooner’s responsibilities include removal and replacement of the iconic power station’s four giant reinforced concrete chimneys.

Steadying himself against the scaffolding of a jump-form rig perched on top of the power station’s south-west chimney, 101m above the mud and clatter of the construction activity below, Spooner appears to pay little heed to the strengthening wind as he eagerly expounds on how the first of the power station’s giant chimneys was carefully dismantled and is now being rebuilt to precisely replicate the original.

Copying the past

To ensure the chimney is visually identical, the replacement is being built using techniques that would have been familiar to those that constructed the 50m high original back in 1931. As Spooner explains, deference to the original even includes “pouring the concrete from wheelbarrows into shuttering, which is then lifted in 4ft jumps” in order to ensure pour marks in the original chimney’s concrete surface are replicated in its replacement.

Reconstruction has been quite a task. Holding tightly to a piece of crumpled paper snaffled from the pocket of his high-vis jacket, hard hat strapped tightly beneath his bearded chin, Spooner shouts out more construction statistics: “We’ve used 282m3 of concrete, weighing over 680 tonnes, placed in 6m3 pours by eight operatives using eight wheelbarrows.” The statistic he seems most proud of, however, is that “the same eight wheelbarrows have been used throughout the chimney’s reconstruction”.

The south-west chimney is set to be completed later this month with the addition of the two cornice rings, which will make it visually identical to the chimney it replaced, only better because it will be structurally sound. It is the first of the power station’s four chimneys to be dismantled and rebuilt as part of the £8bn redevelopment of the 42-acre south-west London site. When it is completed in 2025, the development will include new homes, shops, offices and public spaces and even a new underground station.

Battersea Power Station’s grade II*-listed status meant that the site’s development manager, Battersea Power Station Development Company (BPSDC), had little choice but to incorporate the power station and its four crumbling chimneys into the site’s redevelopment.

Philip Gullett, chief operating officer at BPSDC, is upbeat about the requirement to retain the chimneys because “they are integral to the icon and identity that is Battersea Power Station which gives the development its unique profile,” he says.

The Battersea brand

It is a brand the developers are exploiting to the full; everything connected with the project, even the cups and saucers in the marketing suite, are emblazoned with the power station logo. “If Historic England and the listed status of the building had not required the chimneys to be retained, we’d have still kept them because they define the shape of the iconic power station which forms the identity of the site,” Gullett explains.

To prove his point, Gullett says BPSDC is marketing the apartments being constructed west of the giant power station under Phase 1 of the development: “Generally, the units that face the power station sell at a premium,” he says.

In addition to providing the branding, retention of the chimneys is proving beneficial in other ways. In a nod to the chimneys’ original purpose, two of the reinstated chimneys will be used to conceal the flues from the combined heat and power plants that will generate electricity and heat for the site. A third chimney will house the lift to whisk the public up to a chimney-top rotating observation platform.

The costly decision to dismantle and rebuild the steel-reinforced concrete chimneys was taken after detailed structural surveys showed the structures to be beyond repair. Tests by engineer Buro Happold showed that after half a century’s service, discharging 500 tonnes of CO2 per hour, the sulphurous emissions combined with the use of high salt-content water in the original concrete mix and years of exposure to the weather had all taken their toll. The reinforcing steel was found to be corroded and had expanded in places, particularly on the outside of the chimney, causing cracks in the chimney’s concrete shell.

The extent of corrosion meant repair would only ever have been a short-term fix; the only viable long-term solution was to dismantle and rebuild the structures. “If they are going to be safeguarded on the skyline for future generations, it has become clear that they need to bedismantled and rebuilt,” says Justin Phillips, partner and director of environment and infrastructure at Buro Happold.

Historic England and planning and conservation officers from the London Borough of Wandsworth agreed that the south-west chimney could be dismantled and rebuilt first. Only if the reconstruction was deemed successful would the conservation officers permit work to commence on dismantling and rebuilding the remaining three chimneys.

This apparently onerous condition had its advantages aside from allowing BPSDC to demonstrate to Historic England and council conservation officers that the replacement did perfectly replicate the stack before the other chimneys were demolished. Having a successfully rebuilt chimney would also demonstrate to the public that the developer was serious about preserving this much-loved landmark, particularly as the remaining three stacks are to be simultaneously dismantled.

In fact, the London Borough of Wandsworth was so keen to assuage public concerns that

this icon would be preserved, it insisted the developer put in place a bond sufficient to cover the cost of the chimneys’ replacement before the works commenced.

For Spooner and the team charged with the task of dismantling and rebuilding the south-west chimney the pressure was on. Before the chimney could be dismantled, it was surveyed to accurately capture its dimensions. In 2014, a crash deck was built at the base of the chimney to enable a self-climbing platform (SCP) incorporating a series of hydraulic jacks to be assembled around the foot of the circular stack.

Digital survey equipment mounted on the platform was then used to capture dimensions of the chimney as it climbed to the top of the stack. Flakes of the original paint were also scraped from the chimney and sent for analysis to ensure the colour of the replacement chimneys would perfectly match the originals.

Down the chimney

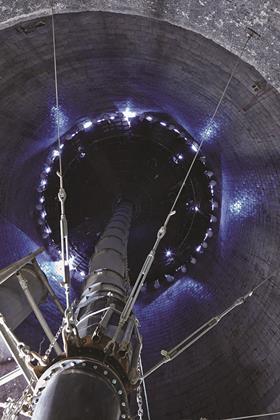

Dismantling of the chimney began with the SCP at the top of the chimney. Steeplejack Delta International used a remote-controlled rotating Brokk demolition machine mounted inside the chimney on a platform supported from the SCP. As the machine’s hydraulic jaws nibbled away at the chimney’s concrete walls, demolition debris was funnelled down a chute in the centre of the stack to ground level where it was used to construct the site’s access roads, while the steel reinforcement was sent for recycling.

The circular chimneys stand on a cross-braced steel ring-beam set into the 51m high rectangular brick-built base structures, which Spooner calls “wash towers”. Demolition of the 50m high chimney continued for another 10m inside of the wash towers to remove every last vestige of the original reinforced concrete and to expose the 8.4m diameter ring beam so it could be restored and repaired prior to the chimney’s reinstatement.

Contractor Beroa Bierrum was responsible for construction of the replacement chimney.

Working from the rebuild rig, its team poured C40/50 mix concrete from wheelbarrows into the 1.2m-high ring of wooden shuttering assembled around two concentric rings of vertical steel reinforcement with circular steel lacing. The task was made more challenging by the chimney’s tapering walls. These taper inwards at an angle of two degrees (both internally and externally) over the height of the chimney; from 30cm thick at the 8.4m diameter base to just 15cm thick at the chimney’s 7m diameter top. To achieve this taper Beroa Bierrum had to trim each of the 40 shutters by 3mm on every shuttering jump.

The first concrete pour took place on 14 May this year. Once the south-west chimney had reached a height of 25m above the brick wash tower, it was inspected by London Borough of Wandsworth.

On 28 September, the conservation offices endorsed the replacement chimney, clearing the way for work to commence on the remaining three chimneys. Some 6,174 wheelbarrow loads later, the forty-second and final jump was completed on 14 November. The task now is to lower the SCP partway down the chimney so that work can commence on casting the two cornice rings that will crown the top of the new chimney. “Shuttering to form the cornice is stacked in preparation on the crash deck below,” explains Spooner.

The chimney will remain as bare grey concrete until the remaining three chimneys have been replaced. Only then will all four chimneys be dressed in a coat of ochre-coloured paint to return them to a colour the power station’s architect, Giles Gilbert Scott, would recognise.

From his windswept chimney-top perch Spooner points out teams of workers dismantling the three remaining chimneys. Each chimney will already have been surveyed to capture the nuances in its construction resulting from changes in construction methods and materials over the 25-year period that elapsed between construction of the first and the fourth chimney (see box, below).

The remaining three chimneys are set to be reconstructed by late 2016. If the team is to meet this deadline, Spooner may well need to add to his collection of eight wheelbarrows. For now, though, as we return to the hoist, Spooner is still citing statistics: “From the first to the last concrete pour this hoist has travelled the equivalent of 21 miles he says.” With the wind now gusting at 38mph, Spooner’s final statistic is a cue to return swiftly to terra firma.

Project team

Client BPSDC

Structural engineer Buro Happold

Construction manager Phase 2 enabling works Skanska

Chimney replacement contractor Beroa Bierrum

Chimney demolition subcontractor to Beroa Bierrum Delta International

A chimney-potted history of Battersea

- The power station was conceived in 1927 by the London Power Company to meet the capital’s demand for electricity

- It was designed by Giles Gilbert Scott, the architect who designed Liverpool’s Anglican Cathedral, Bankside Power Station (now Tate Modern) and the K2 red telephone box

- The power station was built in two halves; initially only the western half of the power station was built along with the south-west and north-west chimneys. This started generating electricity in 1933. The second half came into service in 1944 at which time a third chimney was completed giving the building the moniker “the three-pin plug”

- The power station survived the Blitz, possibly because

- the plumes of white vapour from the chimneys provided the Luftwaffe with a navigational landmark

- The final chimney was added in 1955 when Gilbert Scott’s four-chimney design was finally realised

- Photographs for the cover of Pink Floyd’s Animals album were taken in 1976. For the photoshoot, an inflatable pink pig, made by the Zeppelin company, was tethered to one of the southern chimneys. However, the pig broke free of its moorings and rose into the flight path of London Heathrow airport to the astonishment of pilots in approaching planes

- At its peak the station’s total generating capacity was 509MW

- The station ceased generating electricity in 1983

No comments yet