Cavity walling may have been the preferred option for housebuilders over the course of the 20th century, but that’s all changing now. Peter Caplehorn of Scott Brownrigg considers the advantages of the cavity-free wall

The problem: cavity walls

Perimeter walling is the most extensive element of any house’s fabric, yet little has changed in its basic formula for more than 100 years. The traditional default is an outer skin of brickwork, a cavity filled with insulation and an inner, loadbearing leaf formed of insulating blockwork finished internally with plasterboard. This type of construction developed from the solid brick wall as it combined ease of construction and stability with better weather resistance.

Technical improvements and the demand for higher performing walls may mean that the days of the cavity may be numbered. The main factors to consider are:

• The need to reduce carbon emissions means that a higher performance and more efficient use of materials is needed. Thermal insulation needs to provide the optimum U-value, thought to be 0.16-0.18W/m2K, beyond which the law of diminishing returns starts to come into effect.

• Walls also need to be designed to respond to the thermal cycle of the building. For most buildings the walls should help retain warmth in the winter, and keep the building cool in the heat of the summer. Heavyweight contruction helps to do this, but it is only recently that we have had the analytical tools to work out by how much.

• There is a need to keep excessive sound in and external sounds out.

• For the wall to perform well over many years, moisture vapour must not reach the insulation, and the wall must provide an airtight barrier to prevent excessive heat loss. To achieve this a vapour control layer must be incorporated.

The solution

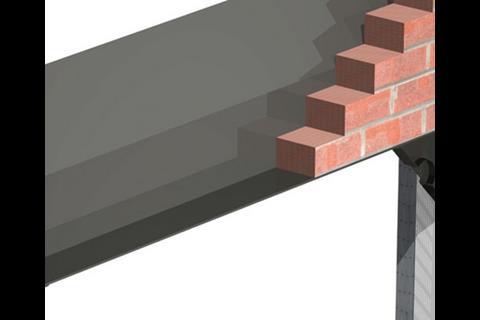

There are clear advantages in ignoring the cavity and designing a wall that simply has a weather-resistant outer skin, insulation, structure and an internal finish. Here are the main advantages:

• Dampproofing External render or rain-screen systems provide proven long-term performance and protect the insulation from moisture.

• Air sealing There is no doubt that air sealing is improved using cavity-free construction with a simple build-up. Fixing a vapour control layer to the inside surface of the masonry wall will ensure that water vapour produced inside the dwelling will not reach the insulation.

• Thermal continuity Placing the insulation on the outside provides better thermal continuity as cold bridging should be less prevalent. Keeping the heavy structure on the inside of the insulation means it will be more effective in damping out temperature peaks and troughs. This will keep the interior cooler in the summer and warmer in winter.

• Ease of construction Although it cannot be claimed that the wall will be thinner, especially as insulation is going to increase in thickness for some time to come, the cavity-free wall is easier to build and can be finished on both sides at the same time, thereby increasing site efficiency.

The wall is monolithic and very practical to construct. Doors and window openings, parapets and roof details are easy to form and simple to make weather-tight. There is no need to include cloaks, trays, and all the other mechanisms associated with cavity walls to ensure that moisture on the wrong side of the cavity is correctly routed outwards. Less operations and simplified construction can reduce waste during construction.

Problems with manufacture

Many factory-produced systems are either too lightweight or not insulated enough. Many of the framed and panelised systems have fallen by the wayside owing to their lack of thermal mass, poor acoustic performance and their Achilles’ heel, condensation. Any failure that leads to poor vapour control will in time cause significant problems and this has been the case on many lightweight walling systems. However this should not prevent the specifier from designing a system from basic principles and or using a high-preformance specification to avoid these problems.

In some circumstances the use of a frame with a board infill, including some degree of mass, may be appropriate. This may be where a more constant internal temperature is required, for instance in retirement housing.

Key points

• Cavity brickwork is no longer the only choice of domestic walling

• Consider the performance speed and clarity of a monolithic construction

• Experience from Europe tells us that solid walls are an entirely proved form of construction

• Designers and specifiers should ensure that thermal, acoustic and water vapour control are understood and allowed for in the specification.

• Performance can be improved, and construction and detailing simplified.

Specifier 16 February 2007

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

Currently reading

Currently readingThe end of the hole-in-the-wall gang

- 15

No comments yet