Manufacturers must create the next generation of products to deliver the homes of tomorrow, writes Paul Barrett, head of product management at ROCKWOOL

Energy efficiency is a particularly prominent issue for housebuilders as they look to satisfy both legislative and buyer demands. Alongside the onerous implications of the Future Homes Standard, energy efficiency is top of mind for buyers too.

Our research found that energy efficiency ratings are key to 76% of consumers when buying or moving home: a figure that has likely only escalated given recent energy price increases[1]. We’re also seeing greater consumer awareness of fire performance given its media attention, meaning purchasers are demanding more from the building fabric of their future home.

Against this multi-layered backdrop, now, more than ever, housebuilders need building product manufacturers to innovate, presenting new options to help them overcome emerging and growing challenges.

New and improved

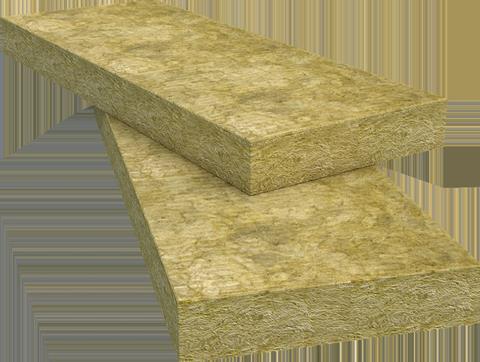

With this in mind, we recently launched , an evolution in stone wool composition that gives the most thermally efficient stone wool insulation currently available in the UK. Made using a new patented production process, products with NyRock technology have a more efficient fibre structure that can deliver thermal conductivity as low as 0.032 W/mK.

With NyRock technology and specifically , our stone wool slab is BBA certified for both full and partial fill masonry cavity walls, we are able to offer a new low level of thermal performance for stone wool alongside a wide range of additional benefits.

Improved performance for thinner walls

Space is a critical commodity, therefore an important commercial benefit for the housing sector is NyRock Cavity Slab 032’s capacity for thinner wall construction. With a 13% improvement in thermal performance over the existing/standard stone wool cavity slab, NyRock Cavity Slab 032 can achieve the target performance of 0.18 W/m²K with a thickness of 150mm, depending on construction type, which is 25mm thinner than typical stone wool cavity products within the same wall build up.

NyRock Cavity Slab 032, like all ROCKWOOL stone wool insulation, is also built for longevity with independent tests showing that the product is durable, rot proof and sufficiently stable to remain effective as insulation for the life of the building[2] and because the product has a high density semi rigid composition, it will not slump in the cavity.

Further, NyRock Cavity Slab 032 comes in 455mm widths to suit standard vertical wall tie spaces and achieves a closely knitted joint with adjacent slabs, without the need for taping of the joints. This helps eliminate gaps allowing for continuity of insulation across the cavity. Stone wool’s high pliability also negates the need for impractical levels of precision cutting on-site, minimising the margin for error and the likelihood of thermal bridging.

Beyond thermal

While thermal capabilities continue to dominate insulation choice, there is growing recognition of wider factors, particularly around fire resistance following the ban on combustible materials in relevant buildings above 18 metres and 11 metres in Scotland.

With the ability to withstand temperatures in excess of 1000°C and achieving the highest Euroclass A1 non-combustible reaction to fire classification, NyRock Cavity Slab 032 gives purchasers added reassurance and developers a marketable benefit. Similarly, stone wool provides acoustic performance due to a non-directional fibre orientation and increased density that traps sound waves and dampens vibrations, significantly reducing outside sources of noise when used in an external wall.

As the Future Homes Standard 2025 draws closer, housebuilders will be reviewing their construction practices to answer more rigorous requirements and complex market drivers. To aid this process, manufacturers must continue to support with the next generation of products to help deliver the next generation of homes.

[1] ROCKWOOL Group, September 2021, survey of 2000 UK adults conducted by OnePoll

[2] BBA Certification 22/6252