As consumers, stakeholders and investors alike continue to gravitate towards a strong environmental conscience, there is a growing onus on dealing with companies which do things ‘the right way’. For the construction industry, this adds greater pressure to advance sustainability priorities and deliver much greener homes at pace.

Although this can, of course, entail new ways of working and investment, it can also pay dividends in the long run – helping to increase profitability, secure a competitive edge and futureproof. Here, Kirstin McCarthy, director of sustainability at Aggregate Industries, explains why it is those construction firms that go the extra green mile that will win the race.

Sustainability is, of course, nothing new. For years now, amid the escalating impacts of climate change, pollution and natural resource scarcity, consumers have been well acquainted with the notion of making environmentally and socially apt choices which help protect people and our planet.

It is only more recently though, that the idea has come into much sharper focus – and for very good reason.

Put simply, global warming continues to move faster than we are. According to the UN, the Paris agreement’s goal of limiting a global temperature rise to 1.5 °C is ‘on life support’. Even the less ambitious goal of a 2°C warming threshold remains worryingly out of reach as the changing climate continues to push ecosystems and communities to their limits.

As a result, consumers are taking a much more active role in supporting the formidable path to net zero ahead – and demanding that the companies that they deal with do too.

For businesses, more than ever this means sustainability is not only about reducing costs or ensuring legal obligations – but letting customers and stakeholders know that your company cares about the future and is doing the right thing.

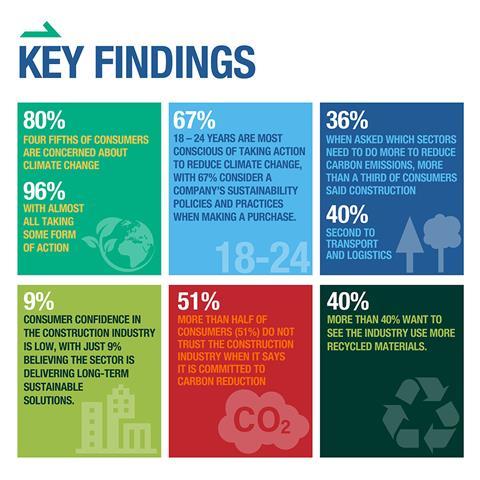

Indicative of this, earlier this year Aggregate Industries commissioned a which asked consumers their views on all aspects of sustainability. Four in five (80%) said they are concerned about climate change - with almost all (96%) taking some form of action. Two thirds (67%) admitted they consider a company’s sustainability policies and practices when making a purchase. Notably, for four in five (79%) of 25–34-year-olds – often dubbed ‘generation green’ – they noted this can have a great deal of influence on decision making.

This sentiment is further reflected on the stock market where a bold green stance becomes more imperative for success, with a recent analysis revealing a direct link between pro-sustainability activity and positive stock prices impact3.

For the construction industry, this shift continues to add pressure to advance environmental priorities and build greener. After all, the sector accounts for nearly 40% of global energy and process-related emissions4 and will play a crucial role in delivering the Government’s net zero ambitions by 2050.

Unfortunately then, despite the vast contribution that the construction sector has had in terms of emissions reductions, the reality – according to our research – is that less than one in 10 (9%) consumers feel that it is delivering long term sustainable solutions. A further half (51%) do not trust the industry when it says it is committed to carbon reduction.

Whether a perception or reality, if the construction sector is to change this it’s clear that it must do more to progress and prove its sustainable actions - but how?

Constructing the case for sustainability

The first challenge our customers face is making the business case for greater sustainability. It may be everywhere, after all, but that doesn’t necessarily mean key decisionmakers will have a full grasp of the latest green building processes and solutions available and, more importantly, how it could benefit their business. For some, it may be difficult to look past the transitional costs in going greener. Others may struggle to see how profitability could go hand in hand with sustainability.

However, the reality is that the latest eco-solutions can help construction businesses work smarter, not harder. Take, for example, the use of green construction products, where the ability to reuse existing materials can not only drastically reduce the raw material output but the associated logistical requirement. This can be found in Aggregate Industries’ recent work in creating a low carbon pavement solution for the resurfacing of the – where 17,432 tonnes of material were reused and over 82,000 road miles were saved. And this is just one of many examples where a more sustainable approach can have a serious impact on materials use, emissions and bottom line.

The good news too is that some early adopters are sharing the value of new green building processes and technologies to their businesses through studies, reports and white papers, so industry knowledge is increasing all the time. This can be used to make a more compelling business case and provide tangible evidence as to the – potentially huge – ROI to be had by going greener.

Achieving more with less

Sustainability goals and an increasingly volatile energy market may see more construction businesses pivot to clean energy sources in line with net zero targets. However, curating a circular economy must also play a key part of this solution.

The transition from a “take-make-waste” linear model to a circular one, in which resources are continuously reused for as long as possible, will help to preserve resources and reduce waste. As a secondary benefit, applying circularity can also reduce the high emissions associated with creating new products from virgin materials.

Indicative of this, our poll shows that more than two fifths (42%) of consumers believe the construction industry should be prioritising its use of recycled materials to help improve sustainability efforts over the long-term. Almost two fifths (35%) also say reducing carbon in the product manufacturing process is integral to driving change.

In this vein, the concept of ‘zero to waste’ continues to spread. Across the world, many governments have outlined ambitions to see no ‘avoidable’ waste produced by 2050. Many have even bigger goals.

Here at Aggregate Industries we feel incredibly passionate about playing our part. The circular economy is one of the key pillars of our sustainability policy and it’s an area where we continue to break new ground.

In terms of recycling materials, we are striving to increase recycled content in our products where possible - one example being Foamix asphalt, which can use up to 95% recycled or reclaimed products in the mix design.

In the coming three years to 2025, our goals include increasing the volume of material reclaimed or recycled from 1.5 million tonnes to 3.0 million tonnes, reducing our waste to landfill to zero and embedding a circularity collaboration action network to generate best practice across all our divisions. Alongside this, it is our hope that the wider construction industry follows suit so we can curate a much more agile, regenerative supply chain approach which truly maximises the value of every single resource.

Sustainability as standard

Although the market continues to see an influx of new green building processes and technologies, many still haven’t caught on as commonplace. However, as consumers continue to shift towards greener homes and properties, this must and will change.

According to our research, many consumers appear to expect that the construction industry will make this happen. Less than half (45%) state they would be prepared to pay more for a recycled or recyclable product and only a third (29%) would invest in a lower carbon product – even though the large majority (80%) remain climate concerned. Thus, the onus is on the sector to transition to sustainable products and approaches as standardised practice.

Across Aggregate Industries, we agree that the low carbon option should be the standard. That is why our is now the company standard, with customers having to pay a premium for ‘traditional’ higher carbon hot mix asphalt. While legacy infrastructure allowed us to achieve this with asphalt with minimal investment, other product lines require significant investment in technology and innovation.

For example, equipment to decarbonise - such as the £13m build of the alternative fuels and raw materials (AFR) facility at our Cauldon cement plant, which is expected to deliver 30,000 tonnes of carbon savings annually - will only get us part of the way on our journey to net zero; we need to do much more. We therefore need demand from the market for low carbon products to support this investment, which will ultimately enable us to make low carbon the standard across the board.

The time is now

As we look to the future, there is no disputing the role that the construction industry must play in making net zero happen. For the future-forward operator then, the time to act is now. Aside from futureproofing, progressive sustainable action can help construction businesses to drastically improve their corporate credentials, reduce costs, improve efficiencies and increase confidence in the process as the sector comes under closer consumer scrutiny.

Further information on Aggregate Industries’ new research study can be found within its ‘��ɫ����TV Confidence in a Sustainable Construction Industry’ which is available for free to download. Visit .

1 https://www.businessgreen.com/news/4046908/paris-agreement-climate-goal-life-support-warns-secretary

2 UN Emissions Gap Report, October 2021:

3 Sustainability and Stock Prices. October 2020.

4 https://www.propertyreporter.co.uk/construction/e-construction-industry-needs-to-go-greener.html