White Design worked on the £325,000 scheme using the latest eco-techniques and technology to provide a green benchmark

• Fair Trade Workplace

• Accredited to level 2 of the Green Dragon Environmental Standard

• Uses a locally sourced and prefabricated timber frame and external timber cladding

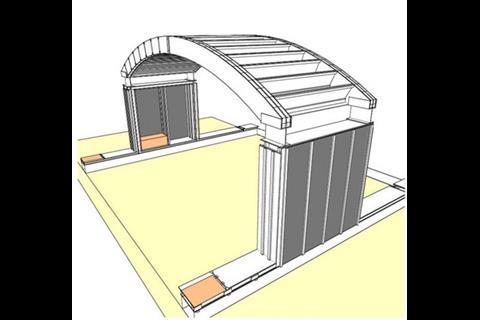

• Unusual roof design using a barrelled set of ‘cassettes’ which incorporates the straw bales

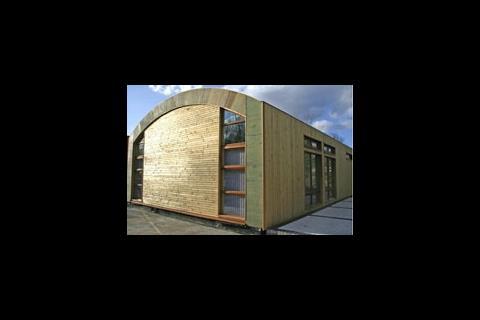

Torfaen Council in Cwmbran, Wales has recently completed its demonstration building called Eco��ɫ����TV. The £325,000 project had a very specific brief for the designer White Design -- to use the latest eco-techniques and technology to provide a green benchmark for the construction industry to follow. The building sets a benchmark for businesses interested in building green.

The Eco��ɫ����TV houses a meeting room for about 30 people, an office for two members of staff, a small kitchen area, and a demonstration area, where there will be an environmental technician to guide visitors. it is a Fair Trade Workplace and is also accredited to level 2 of the Green Dragon Environmental Standard.

Using a straw bale design, Eco��ɫ����TV uses a locally sourced and prefabricated timber frame and external timber cladding, providing an excellent insulated unit, fitted with low energy technology, to reduce the carbon foot print of the building. The building has achieved U-Values for the walls and ceilings of 0.13w/m2/k. The thermal envelope has been regularly tested by the Carbon Trust to see how heat is retained within the building. The Trust uses a thermal camera to pick up the heat signatures coming from the building and has passed these tests on several occasions.

The south elevation uses a large glazed window across the south wall of this long building, with trees on the east elevation for shading from the morning sun. The Eco��ɫ����TV was sited to the south of site as this end is closest to the road, with managers hoping to attract visitors who pass by.

The roof is an unseal design using a barreled set of ‘cassettes’ (pictures bellow) which incorporate the straw bales, in sections across the roof that run the length of the building (see image).

The ventilation of the building is handled by a passive ventilation system, with electrical powered Clerestory windows which respond to an operator reducing over heating during the summer and ventilating during the winter, to exit stale air which may build up in the building. It has a 1000L rainwater harvesting system, which supplies the lavetories with water, using a pulse meter which signals refilling and supplies water from the grid automatically when rainwater is not available. The UV system also treats the water of bacteria and viruses through a filter before it enters the toilet cistern.

The building also has a combined turbine and solar PV system leading to an energy exchange room, which distributes the micro generated energy and any from the grid. But the highly insulated, low energy building should ensure a low energy bill for the building. The team investigated using a biomass boiler. But the size of the building meant that it could not be justified. There are plans to add a solar water heater, if the budget allows.

The building used a preexisting concrete slab which was used for the industrial buildings that were there before. BRE came along and audited the site with its old buildings, before work began to identify materials that could be reclaimed and in what quantities. The buildings that were demolished were harvested for recycled materials and in concert with BRE these materials were traced through their journey to be used on the Eco��ɫ����TV itself or on a second construction site at Caerphilly or Rhondda Cynon Taff in road construction and groundworks. In the demolition, 102 tons of brick and concrete were reused from the site, and 23 tons of metals were reclaimed and some of those metals were used on the new building.

The locally sourced materials used in the building were closely monitored for the purposes of demonstrating how the building resides in the local environment. That it is possible to source materials without importing long range sources. It then measures the mileage and displays that mileage as part of the demonstration ethos of the project to visitors and delegates. There are also window panels through the internal walls showing the straw bales underneath to demonstrate the technology to interested visitors.

Funding was obtained via a number of sources. The £325,000 budget was sourced from the Welsh Assembly which matched the Interreg IIIB programme funding (a European government grant), with some funding coming from the Carbon Trust. For this reason and the continuing redevelopment of the site, the building is moveable. As part of the brief the Eco��ɫ����TV funders wanted the building to be able to be relocated after a few years at the Springvale industrial estate to continue its demonstration brief in other areas and its prefabricated design allows this building to be dismantled and moved from place to place.

This building is designed and built to encourage others to use all or part of the techniques, technologies and practices of green building in general, even down to tracing where the reclaimed materials end up. It is for this reason the Eco��ɫ����TV at Torfaen is the perfect case study, because that is what the building functions as: a portable case study, which can be moved to other areas to begin to attract interested business leaders and constructors. A building which should lead the local construction industry and other business leaders in the areas it visits toward adopting green building methods for their own projects. The project has not been designated a new site to move to yet, but as the funding has come from the Welsh Assembly it will no doubt remain in Wales for the foreseeable future.

The budget breaks down in the following way:

The cost per sq m is just under £1500.

Superstructures: 127,746

Finishes: 11,051

Fixtures and fittings: 10,000

Mechanical and electrical: 35,000

External works: 22,000

Site services: 13,000

Preliminaries: 70,000

Contingency: 20,216

Total: 327,727

No comments yet