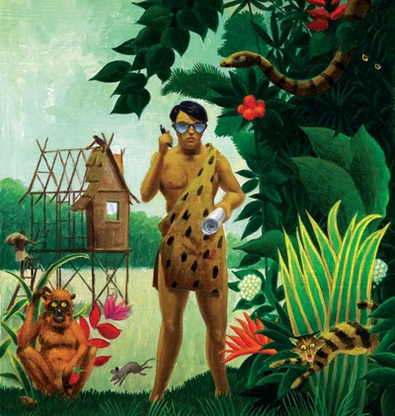

A strong urge to get back to nature ŌĆō or at least become more sustainable ŌĆō has gripped clients this year. Katie Puckett and Caroline Stocks discover how 50 of the biggest spenders are focusing their ┬Ż12.1bn combined construction budget on all things green

It is vital or important to more than three-quarters of your clients. They spend millions of pounds on it every year. And theyŌĆÖre going to judge you on your approach to it. The only problem is, they donŌĆÖt know what it means.

Sustainability is clearly rising up the agenda. But the 50 organisations in Ą■│▄Š▒▒¶╗ÕŠ▒▓į▓ĄŌĆÖs survey of the biggest spenders in construction gave a bewildering variety of responses when asked to describe what it meant. Recycling was the top answer, with 17% of the vote; environment came second with 15% and future-proof third with 11%, but the vote was split between 18 entries.

Confusing, yes. But contractors and consultants should take note. Together, these clients will spend ┬Ż12.1bn on construction this year, across 9000 projects ŌĆō 13% of the industryŌĆÖs total output. Sustainability is becoming a key selection criterion for these companies. Just over a quarter said a contractorŌĆÖs sustainability credentials were ŌĆ£vitalŌĆØ and only 8% said they were irrelevant.

Spending on sustainability is increasing ŌĆō dramatically in some cases. Supermarket Asda, for example, spent only ┬Ż200,000 on sustainability in 2005, a minuscule fraction of its ┬Ż400m construction budget. This year it will invest ┬Ż26m, nearly 6% of its total spend.

AsdaŌĆÖs big push towards greener building was prompted by a pledge made by its US parent Wal-Mart last October. In this country, Bob Simpson, AsdaŌĆÖs head of change management, is in charge of sustainability. He says it applies to energy use, materials and construction methods, which will be developed in a series of prototype stores.

We can send people to the moon, why canŌĆÖt we eliminate site waste by planning, ensuring products are put together in a simplified way and reducing labour on site?

Bob Simpson, Asda

ŌĆ£ItŌĆÖs a bit of a journey,ŌĆØ he says. ŌĆ£The first part of our job is to make sure weŌĆÖre engaged internally, the next stage is to get it out to contractors and suppliers and the second and third tier of suppliers.ŌĆØ

Asda is holding a conference for its suppliers later this year on the subject.

ŌĆ£WeŌĆÖll be saying: ŌĆśYouŌĆÖve seen our aspirations, how are you going meet our aspirations with your own?ŌĆÖ. We want like-minded people.ŌĆØ

Like Asda, most clients take responsibility for sustainability. No less than 71% said it was up to them rather than their suppliers.

We want innovation and alignment of values not only from contractors but from architects, , the supply chain and most definitely manufacturers

John Lorimer, Manchester council

Manchester council too will be spending much more of its ┬Ż280m budget on sustainability this year than last year, up from ┬Ż4.6m to ┬Ż14m. Schools are the biggest area of investment for the council but it will enforce its green policy on all developments in the city. Capital programme director John Lorimer says it has been working with framework contractors and consultants to make each project more sustainable, whether through reducing water consumption or through specifying biomass boilers, photovoltaic panels, wind turbines or green roofs.

ŌĆ£WeŌĆÖve been spending a huge amount of effort on the design process, looking at how we initially select components,ŌĆØ says Lorimer. ŌĆ£Take windows. WeŌĆÖre very keen to analyse the life-cycle costs of each product always with the sustainable agenda in our minds. WeŌĆÖre going for aluminium windows made from 100% recycled material. We certainly wouldnŌĆÖt use PVCu. We will often be paying a premium for more sustainable products.ŌĆØ

Clients will be demanding a lot more from contractors on all fronts. In our survey, the top areas singled out were recycling and waste management. This is a big gripe for AsdaŌĆÖs Simpson. ŌĆ£We can send people to the moon, why canŌĆÖt we eliminate site waste by planning, detailing, ensuring products are put together in a simplified way and reducing labour on site?ŌĆØ he complains. ŌĆ£We donŌĆÖt know how much waste we produce, not just in skips but in efficiency.ŌĆØ

Our clients want a multi-skip approach on site, better training for employees, local labour and biodiesel instead of regular fuel. Procurement directors should have qualifications and a proven track record. They want sustainability considered at the design stage, true whole-life costs and cost-honesty from contractors. Sustainability criteria should be used to select subcontractors too.

Lorimer says: ŌĆ£We want innovation and alignment of values not only from contractors but from architects, engineers, the supply chain and most definitely manufacturers ŌĆō theyŌĆÖre the really key bit in the chain.ŌĆØ

Finally, itŌĆÖs not enough just to do it, clients also said they wanted to see more evidence of construction firmsŌĆÖ efforts. ŌĆ£There are some fine words,ŌĆØ says Simpson, ŌĆ£but not a great deal of doing within the context of the policy.ŌĆØ He suggests cutting phrases such as ŌĆ£to the very best of our endeavoursŌĆØ and replace them with firm commitments: ŌĆ£We will reduce our carbon use by X% ŌĆ”ŌĆØ

Downloads

How important are a contractorŌĆÖs credentials in sustainability?

Other, Size 0 kbWho should drive sustainability in building: client or supply chain?

Other, Size 0 kbWhat three things could contractors do to improve their approach to sustainability?

Other, Size 0 kbWhat five words would you use to describe sustainability?

Other, Size 0 kbWhat three things could the government do to enable more investment in regeneration?

Other, Size 0 kbWhat three changes would help you to develop regeneration sites?

Other, Size 0 kbWhat are the top three things you look for in a contractor regeneration projects?

Other, Size 0 kbWhich procurement method do you prefer to use?

Other, Size 0 kb

No comments yet