Replacing a kiosk at St PaulÔÇÖs Cathedral demanded an intricate, well-prepared crane operation ÔÇô wings and prayers didnÔÇÖt come into it.

ItÔÇÖs eight oÔÇÖclock on Sunday evening and St PaulÔÇÖs Cathedral has been abandoned by the tourists and the touts, the City financiers and their data entry clerks, and the constant stream of buses, lorries and cars have melted into the night. This is about as peaceful as it gets around here.

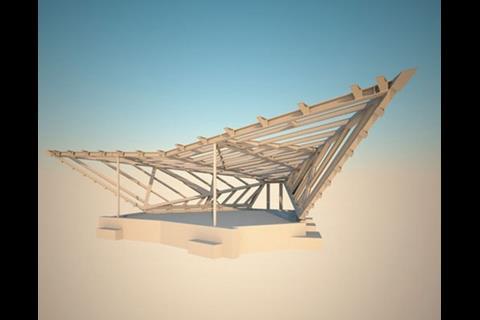

Two extra-long articulated lorries are parked in the lay-by directly south of the cathedral. Each is carrying a giant steel frame, 22m long and sloping upwards to a sharp point. They have just brought the frames from Bolton, where Watson Steel made them in its workshops.

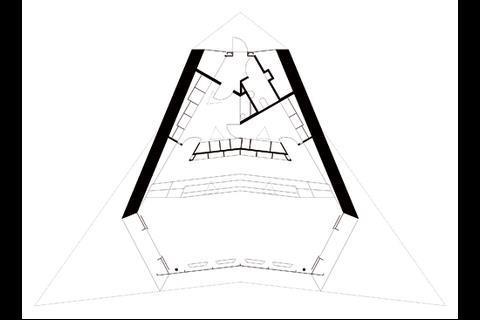

The first lorry drives a few yards across the road and stops next to the hoarding of a building site. Beyond the hoarding, a concrete ground-floor slab has been cast to take what will be a replacement for the Corporation of LondonÔÇÖs information kiosk. And along one side of the site stands a hundred tonnes of gleaming yellow mobile crane.

In the light of powerful spotlights, four men from Watson Steel approach the lorry and attach webbing straps to four members of the frame. The crane silently extends its powerful black steel jib some 50m into the sky, and the men attach four cables suspended from a hefty crane hook to the four straps.

The crane then picks up the 8.5 tonne frame and delicately swings it round a lamp-post and over the hoarding. Guided by the two men on the ground, it gently lays the frame to rest on four timber joists lying on the earth next to the concrete floor slab.

Next, the crane lifts several steel beams and columns from the lorry and deposits them on the ground alongside the frame. Two men pick up four steel columns one at a time and fix them in position by roughly hammering steel bolts to steel plates fixed to the ground-floor slab. These columns slope at giddy angles as they are no more than temporary props.

The critical operation of lifting the frame into its permanent location comes next. The crane slowly lifts the frame up and gingerly swings it round below the branches of a huge London plane tree, which loses a few twigs in the manoeuvre. It then suspends the frame in mid-air a couple of metres above the concrete upstand edge beam of the floor slab, where it is stayed by the two temporary props.

If some of the concrete had needed hacking out and recasting, it would have been a catastrophe

Louis Harrison, Skanska

Then one corner of the frame is gingerly lowered and guided by the four men so that a cleat at its bottom corner clangs into a steel plate cast on to the edge beam. With a wrench as big as a manÔÇÖs arm, and a certain amount of banging, the men bolt the angle cleat to the steel plate. They then adjust the bases of the temporary props and manhandle one of them where it had become caught between two of the members of the frame. Suddenly, the whole frame lurches into its final position where the cleats engage neatly with the other 12 steel bolts fixed to the ground beam.

The crane operation of lifting, swinging round and lowering the frame is carried out with all the grace of a well-rehearsed ballet. ÔÇťThere was no dry run,ÔÇŁ says Louis Harrison, for contractor Skanska. ÔÇťIt had been worked out in advance by computer and the crane operator had a computer screen on the dashboard of his cabin. Also, Watson Steel had worked out the centres of gravity of the steel frames to show where the sling locations should be. So there was no swing or sway when the frames were lifted.ÔÇŁ

The operation is repeated for the second steel frame, which is fixed to the opposite side of the floor slab. After that, a third lorry arrives and 50 steel beams are lifted on to the site in 10 separate lifts. Several of the beams are bolted into position to span the two side frames. Work goes on until 12.30am.

As for the bolt connections between each of the two steel frames and the concrete edge beams, Harrison explains that the seven pairs of 24mm diameter bolts had previously been cast into the edge beams, with a tolerance of ┬▒ 15mm. The exact tolerance had been achieved by threading each bolt through a hole in a metal plate that had been cast into the edge beam. ÔÇťI was surprised at how neatly it all fitted together on the night,ÔÇŁ says Harrison. ÔÇťIf it hadnÔÇÖt and some of the concrete had needed hacking out and recasting, it would have been a catastrophe. But Skanska, Keltbray [the groundworks contractor] and Watson Steel had all checked the bolt fixings, and those checks paid off.ÔÇŁ

Work resumes on Tuesday. This time a mobile crane is hired to lift the other steel members into the roof structure, assisted by the two cherrypickers. Once the entire roof is in place, the fixing bolts are tightened. By 3.30pm on Wednesday, the entire steel frame of the building is complete. ÔÇťThe structural frame went up in two-and-a-half days,ÔÇŁ says Harrison. ÔÇťThatÔÇÖs all quite an achievement.ÔÇŁ

The next phases of construction will be to sheath the frame in plywood and stainless steel panels. Finally, fitting out and landscaping will be carried out for CityÔÇÖs new information kiosk to open in June.

No comments yet