Barhale installedan efficient sewage tunneling system that overcame the challenge of soft soil.

Due to the presence of clay, a high pressure jetting system was introduced to the face of the tunnel boring machine (TBM) in order to increase the ability of the machine to deal with the softer than expected ground, which has a tendency to block the cutter head if the jetting system is not used. The result was an additional 4m3 /hour of water being added to the slurry system.

Key points

• Introducing a high pressure jetting system to the face of the TBM to deal with softer soil

• Optimising the recycling of slurry to ensure it is efficiently separated when it returns to the surface

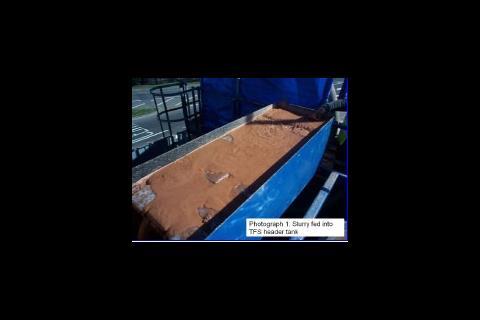

• The installation of a Tangential Flow Separator (TFS) to overcome the problem of disposing high level of solids within the slurry.

• Improving the TFS set-up by adding flocculants to the header tank to help bind very small solid particles together increasing their weight thereby aiding their separation.

Contractor: Barhale

Downloads

Barhale clean effluent

Other, Size 0 kb