The latest module in our CPD series considers the importance of consistent, accurate data in the BIM process, and the key role played by manufacturers in providing it. This module is sponsored by British Gypsum

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 30 MINUTES

DEADLINE: 28 NOVEMBER 2014

INTRODUCTION

The use of BIM is increasing rapidly across the construction sector. By 2016 it will be compulsory for fully collaborative BIM processes to be used on all government projects greater than £5m in value. Beyond this target, the wider industry is adopting BIM as a way to more accurately predict and ensure performance throughout the life of a building, from initial design to operation and even deconstruction. Last year, a report by marketing consultancy Competitive Advantage estimated that the market penetration of BIM would increase from just under 4% of all UK construction projects in 2013 to just over half by 2016, with a total value of £27bn.

BIM can decrease waste, increase building efficiency and assist collaborative working throughout the design and construction process. By ensuring information is captured and organised during construction, it supports better management during the building’s lifetime and offers greater potential to recycle components and materials at the refurbishment or demolition stage.

Data is at the heart of the BIM process. A key benefit of BIM is consistency of data throughout a project, and the avoidance of data loss as the building moves from design to construction to management. However, it is vital that the data fed into the model is itself accurate and consistent, if the full potential of BIM is to be realised.

This CPD will consider the role of data in BIM, the standards governing how BIM data should be stored and exchanged, and the role that manufacturers can play in supplying detailed, up-to-date information about their products.

BIM AND DATA

The government strategy paper published in March 2011 defined four maturity levels of BIM, based not only on the level of technology used to design a building, but the level of collaboration within the process. These are:

- Level 0 Unmanaged 2D CAD, with data exchanged in paper or electronic paper form.

- Level 1 Managed CAD in 2D or 3D format, with data shared via a collaborative tool to provide a common data environment (CDE) with a standardised approach to data structure and format. No integration of commercial data.

- Level 2 Managed 3D environment where each discipline creates its own models, and all project information is shared electronically in a CDE. Commercial data is managed by enterprise resource planning software and integrated into the BIM by a proprietary interface or bespoke software. Level 2 BIM may use 4D construction sequencing and/or 5D cost information. This level of BIM is the target for 2016.

- Level 3 Fully integrated, collaborative process with models shared between the project team on a web-enabled BIM hub, compliant with the Industry Foundation Classes (IFC) open data standard (see overleaf). Level 3 Bim will use 4D construction sequencing, 5D cost, and 6D project lifecycle management information.

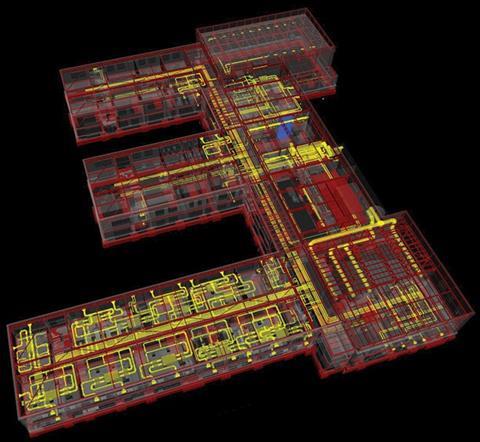

As this progression implies, the crucial difference between traditional 3D modelling and level 2 BIM is data. In CAD software, models were treated as collections of dumb surfaces or solids, but BIM software can differentiate between different types of element and store a great deal of information about their real-world properties and behaviour. The key to BIM is therefore not the visual model, but the database of information that sits behind it. This enables different organisations working on the same project but using different software to store and retrieve information in a consistent, shareable format.

One type of data input into the building information model concerns the products, materials and assemblies that will form part of the finished building. It is essential that the library of product information within the model is appropriate, accurate and up-to-date, or errors will emerge during construction or operation.

As the use of BIM progresses from level 2 to level 3, it is clear that the depth and range of product information required by the designer will continually grow - from dimensional data to performance data on aspects such as thermal and structural properties, acoustics, embodied carbon and recyclability. This presents a challenge to manufacturers, to offer not only product geometry but product-specific data too, in a format that can be easily used by building designers.

BIM OBJECTS

A BIM object is a set of product information in a BIM format, which can be imported into a model by a building designer. It contains a range of data about a product, including its geometrical data about its physical characteristics, visualisation data that gives the object a recognisable appearance, and behavioural data about how it will behave in real life and where it can be placed.

There are two main types of object: component and layered. Component objects are building products that have defined geometrical shapes, such as windows, doors, boiler, and so on. Layered objects, or material layer sets, are building products without a fixed shape or size, such as carpets, roofing, walls or ceilings.

Architects can create BIM objects themselves, or download objects or collections of objects from online libraries or directly from manufacturers.

One solution is to use a library of generic product data, which combines average or typical data taken from across the market, encompassing different versions of similar products. A third party would take on the task of collating, interpreting and analysing the data to form a set of typical numbers that can then be input into the BIM model. The disadvantage with this is that this data is not specific to any one product, increasing the risk of inaccuracy in the model.

An alternative is to go to manufacturers themselves as a source of accurate, high-quality and up-to-date information on individual products. Many manufacturers are developing ways to make this information available online so that designers can always access the latest product details. For example, in January 2014, British Gypsum launched the White Book System Selector, an online tool designed to streamline the specification process by allowing specifiers to search and filter through its plaster, drylining and ceiling system solutions, and download BIM objects, CAD drawings, NBS specification clauses, and product data schedules.

Whatever the source of BIM object data, it is provided in a consistent format that can be used by different disciplines in different software packages. There are a number of industry initiatives to develop standard file formats for

data, as described below.

IFC

The standard file format Industry Foundation Classes (IFC) provides a common language for BIM object data. IFC was developed to ensure that BIM data could be read by all parties involved in a project, regardless of the software they are using. IFC is a platform-neutral, open file format which is developed and maintained by the industry consortium buildingSMART, originally founded by software company Autodesk in 1994 as the Industry Alliance for Interoperability. The latest version of the IFC data model, IFC4, was released in March 2013. The IFC format is registered as the British and International standard BS ISO 16739:2013.

COBie

COBie, or Construction Operations ��ɫ����TV Information Exchange, is a common data format for the publication of BIM information. This applies not to geometric modelling but to the database behind the model, and enables it to be delivered in a structured format. COBie helps to capture and record project data at the point of origin, including equipment lists, product data sheets, warranties, lists of spare parts and maintenance schedules, which is essential to support future operations, maintenance and asset management.

It was developed by the US Corps of Engineering to manage the data coming from BIM models into the client organisation, particularly for the handover of operation and maintenance information. The UK government BIM Task Group has published an extended version, known as COBie UK 2012, which must be used as part of achieving level 2 BIM. COBie UK 2012 is essentially a standard questionnaire which must be completed in four “data drops” at key points during the delivery stage of the project. The data is exchanged as a spreadsheet to minimise complexity and training requirements. The use of COBie is essential to meet the government’s level 2 BIM target.

Product data templates/schedules

Product data templates (PDTs) were conceived by the CIBSE BIM Group to simplify the data collection requirements of level 2 BIM and COBie UK 2012, and are now being developed by the BIM 4 Manufacturers and Manufacturing (BIM4M2) working group.

A PDT is a standard product “questionnaire” for each equipment type, which brings together all of the information that would be required about a product by every party in the BIM process, from specification to operation to decommissioning and replacement. Because they are in spreadsheet format, they can be used with all BIM platforms and users can automate data extraction to pull out only the information required. Because PDTs contain all information that would be required for compliance with level 2 BIM, manufacturers need only complete a PDT for each of their products once. Once a PDT is completed, it becomes a product data schedule (PDS).

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 30 MINUTES

DEADLINE: 28 NOVEMBER 2014.

Privacy policy

Information you supply to UBM Information Ltd may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. UBM Information Ltd may send updates about ��ɫ����TV CPD and other relevant UBM products and services. By providing your email address you consent to being contacted by email by UBM Information Ltd or other third parties. If at any time you no longer wish to receive anything from UBM Information Ltd or to have your data made available to third parties, contact the Data Protection Coordinator, UBM Information Ltd, FREEPOST LON 15637, Tonbridge, TN9 1BR, Freephone 0800 279 0357 or email ubmidpa@ubm.com. View our full privacy policy at

No comments yet