This CPD module explores the wider benefits that insulation systems based on thinner, high-performance materials such as phenolic foam can bring to property developers and owners. It is sponsored by Kingspan Insulation

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 23 OCTOBER 2015

INTRODUCTION

Thermal performance is an increasingly important issue for designers of commercial buildings. Part L2A 2013 of the ��ɫ����TV Regulations, which came into force in April 2014, imposed a further 12% reduction in carbon emissions in deep-plan office buildings with air-conditioning and 13% for shallow-plan offices, compared with the 2010 version. In Wales and Scotland, the requirements are even tougher: the Welsh regulations demand an aggregate uplift of 20% on 2010 levels, while from 1 October 2015, Scottish non-domestic buildings will need to make a 43% improvement.

This creates a requirement for building insulation that can offer greater thermal efficiency. Traditionally, this meant using thicker materials, and thicker walls to accommodate them, leading to the loss of valuable floor space – an important consideration for commercial landlords. However, a new generation of insulation materials has been developed to give high levels of thermal performance without having to compromise the overall wall width.

This CPD will provide an introduction to different types of insulation materials before exploring, with the help of detailed analysis from cost consultant Sweett Group, how thinner insulation materials can unlock investment potential for commercial property owners, by increasing rental returns.

THERMAL CONDUCTIVITY

The measure of the rate at which heat flows through an insulant is known as the thermal conductivity (k-value) or alternatively, the lambda (λ) value. Heat transfer through a volume occurs by three modes: convection, conduction and radiation.

Traditional insulants work by blocking convection by means of a matrix of fibres or bubbles where the voids are filled with air. The performance of an insulant is therefore determined by the thermal conductivity of the air within it, plus the transfer capability of the material itself.

Replacing the air with a less conductive substance, or blowing agent, improves the overall performance of an insulating material. Removing the gas altogether to create a vacuum offers even better performance – both convection and conduction require the presence of gas molecules to transfer heat energy, so neither can take place.

OTHER CONSIDERATIONS

Thermal performance is not the only key driver behind specification of insulation materials.

Other factors include: fire performance; environmental impact; responsible sourcing; global warming potential; compressive strength; moisture resistance, air infiltration and durability; weight and associated load implications; logistics and availability; access to technical support; BBA certification and LABC Registered Detail status.

The other important consideration is cost: often, higher-performing systems will have higher capital costs, although this can be offset by lower energy costs and increases in usable floor area.

TYPES OF INSULATION

Aerogel

Aerogel is a synthetic, porous material derived from a gel, in which the liquid component has been replaced with a gas. It is made of 95-99% air by volume, making it one of the lowest-density materials available. The pores within the material are extremely small, reducing the ability of air molecules to move through the structure, and therefore their ability to transfer heat. An aerogel building insulation blanket offers thermal conductivity as low as 0.014W/m.K.

Expanded polystyrene (EPS)

The manufacturing process of EPS uses expandable beads that incorporate pentane – a hydrocarbon blowing agent. When heated with steam, they expand to 30 times their original size and are then fused together to produce a shaped product or large block. The thermal conductivity of EPS insulation is typically 0.031 to 0.038W/m.K.

Extruded polystyrene (XPS)

Polystyrene granules are melted, mixed with additives and a blowing agent, then extruded under pressure to form rigid foamed polystyrene, which is then cut into boards. The thermal conductivity of XPS insulation is typically 0.029 to 0.038W/m.K.

Mineral fibre

Glass fibre and rock fibre insulation comprise a matrix of fibres, made by spinning a molten inorganic material at high temperature. This is then bonded with an organic resin binding agent.

The thermal performance of mineral fibre relies largely on trapped air within the matrix,. Typically, conductivity ranges from 0.031 to 0.044W/m.K.

Phenolic foam

The manufacture of phenolic insulation begins with a liquid insulation mixture, which is placed between two flexible facing layers. The liquid contains a blowing agent – most commonly pentane – which under the action of a catalyst evaporates to form a matrix of small bubbles or cells. When the reaction stops, a rigid cellular board is created, which can then be cut to size.

This matrix inhibits gas diffusion and therefore leads to very low thermal conductivity levels – typically of between 0.020 and 0.023W/m.K, depending on the thickness of the board.

Rigid urethane (PIR or PUR)

PIR or PUR insulation is made in the same way as phenolic insulation, and has many of the same benefits. The cellular structure of the board is more open, resulting in slighly lower levels of thermal resistance. These range from 0.021 to 0.028W/m.K, depending on thickness and facing material.

Vacuum insulated panel

VIPs are rigid boards that have a microporous core made of three components: fumed silica, an opacifier and organic fibres. This core is evacuated of air, encased and sealed in a thin, gas-tight envelope. The key advantage of VIPs is their low thermal conductivity: lambda values of 0.007W/m.K can be achieved. They also offer other advantages, including a high degree of moisture resistance and fire resistance – the fumed silica core is an ash created by burning a silane, so effectively the material has already been burned.

Product standards exist for EU member states to ensure that declared thermal conductivities are harmonised. However, for some of the newer insulants, such standards are under development.

BENEFITS OF THINNER INSULATION

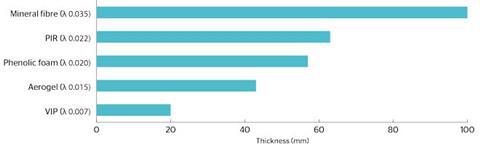

One advantage of materials with lower thermal conductivity is that thinner insulation can be used. Figure 1 shows the required thickness of different materials to achieve the same thermal resistance.

The use of thinner insulation materials can bring a number of benefits, albeit some are more difficult than others to quantify. These include:

- Increased loading capacity in freight vehicles

- Reduction in necessary site-storage space

- Time saving, where insulation materials are integrated using a modular construction approach. Support systems and fixings are also less onerous.

But perhaps the key benefit of thinner insulation is the creation of additional floor area without having to alter the designed footprint of the building – a factor of critical importance in markets such as central London or Edinburgh. The usable space within a building is a fundamental metric in understanding the valuation, thus the investment potential, of real estate. The larger the internal floor area of a property, the higher the rent it can command – and therefore the greater the potential return on investment (ROI).

In order to understand the relationship between the additional cost of thinner, higher performing insulation materials and ROI, Kingspan Insulation commissioned Sweett Group to conduct a cost analysis of different commercial building types with two different approaches to insulation. The materials chosen for the analysis were high-performance phenolic foam and mineral fibre and XPS, due to their widespread market presence.

Sweett Group developed a research programme to, first, analyse a database of 7,290 buildings generated from a model. The model considered a wide range of physical and financial building characteristics such as building use, shape, floor-to-wall ratio and construction cost, as well as rental income and yield in various locations across mainland Britain.

The study then analysed 10 real case study buildings, on which Sweett Group had provided cost consulting services between February 2013 and February 2015. This covered four different types of structure:

- Masonry cavity wall, brick and block

- Timber-frame, brick outer leaf

- Rainscreen ventilated warm-wall steel framing system (SFS)

- Rainscreen ventilated hybrid-wall SFS.

For each, it considered both a range of building characteristics (for example, size and shape) and a range of commercial variables (for example, geographical location, rental value and material cost), that are representative of current commercial buildings.

The results were then interrogated to determine the following:

- Cost uplift: the additional cost of installing the premium insulation, both in terms of the wall construction itself (£/m2) and the overall project development costs (%).

- Capital value of space: the net value (after taxes and fees) that would be received if the floor space was let to market. This was analysed using a range of variables: rental income from £50-750/m2/annum and implicit yield (the ratio of rent to capital value) ranging from 2.5-12.5%

- ROI: This was determined by dividing the capitalised market value of the additional space by the uplift in capital expenditure.

The analysis showed that in many development scenarios the additional cost of the thinner product is rapidly offset by the value of the additional space obtained. In some instances where there is a high implicit yield, then high-performance or thinner products are unlikely to be worth the extra outlay.

Nevertheless, the analysis demonstrated that where space is at a premium there can be a strong business case for thinner insulation products despite their higher capital cost.

- In 92% of the buildings analysed in the database, the premium insulation product delivered a positive ROI

- In 40% of the database buildings this ROI ranged between 300% and 1,000%

- A further 18% of the database buildings experienced ROI in excess of 1,000%, with returns of over 4,000% in some instances

- The 10 real case studies delivered an ROI of between 32% and 1,635%.

Here are some of the key findings for the four different build-ups, showing the effect of thinner insulation on both the database and the case study buildings.

Timber-frame, brick outer leaf

The cost uplift of the phenolic insulation was £11.50/m2, but the overall width of the build–up was 42mm thinner than that incorporating glass mineral fibre.

| Location | ��ɫ����TV type | Rental value per year (£/m2) | Size (m2) | Yield (%) | ROI (%) |

|---|---|---|---|---|---|

| Edinburgh | Business centre | 105.5 | 960 | 7.5 | 23 |

| Milton Keynes | Business park | 154.1 | 10,300 | 5.5 | 78 |

| Peterborough | Laboratory / Small office | 141.8 | 610 | 7 | 38 |

| Bristol | Office | 288.5 | 29,600 | 6.5 | 190 |

| Southampton | Business park / Office | 184.1 | 16,700 | 7 | 90 |

Rainscreen ventilated warm-wall SFS

The cost uplift of the phenolic insulation was £5.50/m2, but the overall width of the build-up was 80mm thinner than that incorporating glass mineral fibre.

| Location | ��ɫ����TV type | Rental value per year (£/m2) | Size (m2) | Yield (%) | ROI (%) |

|---|---|---|---|---|---|

| Glasgow | Retail | 159.3 | 5,550 | 9 | 282 |

| Edinburgh | Business centre | 105.5 | 960 | 7.5 | 257 |

| Manchester | Office / Technology park | 236.8 | 6,200 | 6 | 359 |

| Milton Keynes | Business park | 154.1 | 10,300 | 5.5 | 353 |

| Peterborough | Laboratory / Small office | 141.8 | 610 | 7 | 242 |

| London | Office / Retail | 683.5 | 6,800 | 3.5 | 1,324 |

| Cardiff | Industrial / Office | 61.4 | 35,800 | 8.5 | 32 |

| Bristol | Office | 288.5 | 29,600 | 6.5 | 578 |

| Southampton | Business park / Office | 184.1 | 16,700 | 7 | 418 |

Masonry cavity wall: brick and block

The cost uplift of the phenolic insulation was £6.00/m2, but the overall width of the build-up was 40mm thinner than that incorporating glass mineral fibre.

| Location | ��ɫ����TV type | Rental value per year (£/m2) | Size (m2) | Yield (%) | ROI (%) |

|---|---|---|---|---|---|

| Edinburgh | Business centre | 105.5 | 960 | 7.5 | 103 |

| Manchester | Office / Technology park | 236.8 | 6,200 | 6 | 202 |

| Milton Keynes | Business park | 154.1 | 10,300 | 5.5 | 181 |

| Peterborough | Laboratory / Small office | 141.8 | 610 | 7 | 115 |

| London | Office / Retail | 683.5 | 6,800 | 3.5 | 1,635 |

| Cardiff | Industrial / Office | 61.4 | 35,800 | 8.5 | –37 |

| Bristol | Office | 288.5 | 29,600 | 6.5 | 343 |

| Southampton | Business park / Office | 184.1 | 16,700 | 7 | 207 |

Rainscreen ventilated hybrid-wall SFS

The cost uplift of the phenolic insulation was £10/m2, but the overall width of the build-up was 55mm thinner than that incorporating glass mineral fibre.

| Location | ��ɫ����TV type | Rental value per year (£/m2) | Size (m2) | Yield (%) | ROI (%) |

|---|---|---|---|---|---|

| Glasgow | Retail | 159.3 | 5,550 | 9 | 53 |

| Edinburgh | Business centre | 105.5 | 960 | 7.5 | 74 |

| Manchester | Office / Technology park | 236.8 | 6,200 | 6 | 166 |

| Milton Keynes | Business park | 154.1 | 10,300 | 5.5 | 145 |

| Peterborough | Laboratory / Small office | 141.8 | 610 | 7 | 88 |

| London | Office / Retail | 683.5 | 6,800 | 3.5 | 791 |

| Cardiff | Industrial / Office | 61.4 | 35,800 | 8.5 | –47 |

| Bristol | Office | 288.5 | 29,600 | 6.5 | 290 |

| Southampton | Business park / Office | 184.1 | 16,700 | 7 | 165 |

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 23 OCTOBER 2015

Privacy policy

Information you supply to UBM Information Ltd may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. UBM Information Ltd may send updates about ��ɫ����TV CPD and other relevant UBM products and services. By providing your email address you consent to being contacted by email by UBM Information Ltd or other third parties. If at any time you no longer wish to receive anything from UBM Information Ltd or to have your data made available to third parties, contact the Data Protection Coordinator, UBM Information Ltd, FREEPOST LON 15637, Tonbridge, TN9 1BR, Freephone 0800 279 0357 or email ubmidpa@ubm.com. View our full privacy policy at

No comments yet