Using case studies from a monitoring study of recent installations, this module explores the benefits of heating systems that combine a boiler and an air-to-water heat pump. It is sponsored by Daikin

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 23 SEPTEMBER 2016

INTRODUCTION

Domestic hybrid heating systems combine two complementary technologies: a traditional boiler and an air-to-water heat pump. Depending on a range of factors, these may work individually or together to provide central heating and hot water. The boiler may be powered by gas, or oil or LPG for homes that are off the gas grid. The air-to-water heat pump is powered by electricity, and extracts heat from the air outside to provide a renewable source of energy.

After the initial investment, hybrid systems can therefore be cheaper and less carbon-intensive to run than conventional boilers. Depending on the operating parameters, hybrids can achieve efficiencies of up to 130%, compared to the 90% typical of condensing boilers. By sharing the heat demand across two appliances, hybrids can potentially increase the life of the system and provide resilience by offering a back-up heat source should one appliance break down.

They are suitable for installation in new-build properties or as part of renovation projects.

HOW HYBRID HEATING SYSTEMS WORK

Hybrid heating systems have a single controller which manages the boiler and heat pump operation based on either relative costs for gas and electricity, or the relative carbon intensity value of gas and electricity. At any time, the system can choose to run the most cost-effective or least carbon-intensive heat source. Hybrid systems typically have three modes of operation:

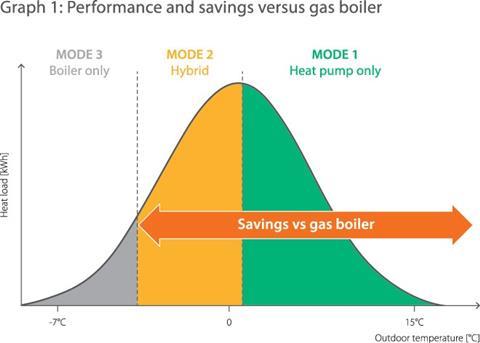

- Mode 1: Heat pump only When outdoor temperatures are higher and heat loads are low, the heat pump is able to fully meet demand, though the combi boiler remains on standby to provide hot water if needed. In this mode, only electricity is used and the hybrid system is at its most efficient.

- Mode 2: Hybrid With lower ambient temperatures, the capacity of the heat pump is not sufficient to meet heating demand on its own, so the boiler fires up to assist. It is still cost-effective to run the heat pump.

- Mode 3: Boiler only When the outdoor temperature drops below a certain point, it is no longer cost-effective to run the heat pump so the boiler takes over completely.

In modes 1 and 2 when the heat pump is working, the hybrid boiler is cheaper and/or less carbon-intensive to run than a conventional boiler. Graph 1 (below) shows the distribution of the heat load for a typical property over the ambient temperature range.

The operation mode and efficiency of a hybrid relies on using the most cost-effective form of heating, depending on relative fuel prices and external conditions. While the efficiency and therefore the running costs of a boiler are relatively constant at all ambient conditions, the efficiency of an air-source heat pump changes depending on the ambient temperature and the required flow temperature. A heat pump operates most efficiently when outdoor temperatures are moderate (typically about +7°C), and design flow temperatures are lowest (typically 40°C). When the outside temperature starts to fall, a higher flow temperature is required to maintain the desired indoor room temperature. However, the efficiency of the heat pump decreases because the compressor needs to work harder. When the ambient temperature drops far enough to cause the heat pump efficiency to fall below the point at which it is the more expensive appliance to run, the boiler takes over.

The following example demonstrates how this works, in the case of a hybrid system that is powered by mains gas and electricity.

Assuming a boiler efficiency of 90%, a household will consume 1.11kWh of gas for every kWh of heating energy. At a gas price of 5p per kWh, the household pays 5.6p/kWh.

A heat pump is more efficient than a combi boiler. For every kW of electricity the heat pump consumes, it generates a certain amount of renewable heat from the air. This ratio is called the coefficient of performance (COP). A heat pump that produces 4kW of heat energy for every kilowatt of electricity it consumes has a COP of 4. In comparison, a boiler typically has a COP of 1. Assuming a coefficient of performance of 4, it will require only 0.25kWh of electricity to produce 1kWh of usable heating energy. At an electricity price of 15p per kWh, the household pays 3.8p/kWh.

In our example, if the COP drops to 2.5, it will take 0.4kWh of electricity to produce 1kWh of useable heat. At the same electricity price of 15p/kWh, the cost per kWh of heat energy rises to 6p. This makes it more expensive than the gas boiler, so when the outside temperature and therefore the COP of the heat pumps falls, it becomes more cost-effective to use the gas boiler.

There is therefore a point at which it is most efficient to switch between the gas boiler and the electric heat pump. This is known as the balancing point. It is not fixed, however, and will vary depending on a range of factors.

If electricity prices drop, the heat pump becomes cheaper and can therefore operate for longer. If the price of electricity increases, so does the running cost of the heat pump, which means it will be cheaper to run the boiler for a longer period of time. The same logic applies as gas prices change – the boiler becomes a less cost-effective option for longer as gas prices increase. Many electricity providers offer tariffs that vary between day and night, and between peak and off-peak periods. In these cases, the relative running costs of the boiler and heat pump will also differ by time of day.

Running a hybrid system to minimise carbon

It is possible to set up some hybrid systems to minimise the use of carbon, rather than running costs. This is done by calculating a balancing point based on the primary energy coefficients of electricity and gas. Gas is a primary energy, with a coefficient of 1. Electricity is a secondary energy, produced from burning primary energy sources. Its coefficient depends on the amount of primary energy needed to produce 1kWh of electricity. The average value in Europe is 2.5. In the future, when more electricity is produced by renewable and nuclear sources, the primary energy value will fall.

CONTROL SYSTEMS

Hybrid systems use different strategies to decide at which point to switch between modes of operation.

Bivalent systems

The simplest method of control has only two running modes – either the boiler or the heat pump, with the switchover programmed to occur at a fixed outside temperature. These systems are known as bivalent, rather than hybrid. They do not take into account relative efficiencies or fuel costs of each system or the current operating conditions.

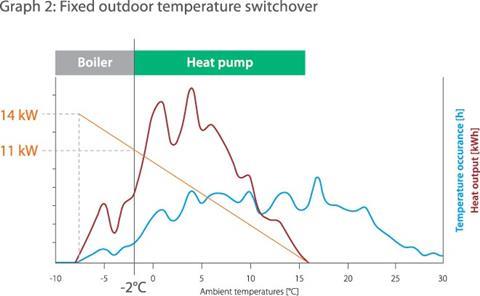

To favour the heat pump, and maximise operating efficiency and cost and carbon savings, the switchover point will often be set quite low – for example, at –2°C. However, this means that the capacity of the heat pump needs to be able to cover the full heating load at –2°C and will therefore be relatively large. Graph 2 (opposite) shows the heating distribution and demand for a typical property. In this instance, at –2°C, the heating energy required by the house will be 11kW. This means that the heat pump must have a capacity of 11kW at –2°C.

Hybrid systems

In many hybrid systems, the heat pump and the boiler work in parallel, usually feeding a buffer vessel or low-loss header. The control system decides which appliance will operate by considering either the relative fuel costs or carbon intensity. Hybrid systems will switch between heat pump or hybrid, or will operate between the three modes described above: heat pump only, both heat pump and boiler, or boiler only. The switchover point is determined by the relative costs of gas and electricity and the efficiency of the heat-pump. The householder or installer can input energy price data and the system will do the rest.

In other systems, the heat pump and boiler are connected in series, rather than in parallel, and there is no additional buffer component to the system. This is the case with the Daikin Altherma hybrid system. This contains a patented technology that manages the flow rate in order to maximise the efficiency of the heat pump when the system is operating in hybrid mode. As described above, this is affected by parameters such as ambient temperature and flow and return temperatures. By controlling the flow rate, the system lowers the return temperatures to allow the heat pump to produce an even greater proportion of energy and therefore optimise the COP.

Hybrids and the Renewable Heat Incentive

Both hybrid and bivalent heat pump systems are eligible for funding under the government’s domestic Renewable Heat Incentive (RHI) scheme, launched in April 2014. This pays householders for the renewable heat energy that they generate from their hybrid heat pump for a seven-year period after installation. The amount of income they receive depends on the latest heat pump tariff and payments are based on metered readings.

For hybrid systems, the RHI tariff rate is the same as for a standalone air-to-water heat pump. In April 2016, this was 7.51p/kWh of renewable heat. This is paid only on the amount of measured renewable heat generated. Metering is required to determine the actual amount that is generated, and hybrid systems must include both a class 3 heat meter and a class A electricity meter as a minimum. The arrangement of the meters will vary between systems. To receive domestic RHI funding, both the product and the installer must be accredited under the Microgeneration Certification Scheme (MCS). This is a government-backed scheme, intended to ensure minimum product performance standards and consistent design and installation.

When the scheme was first launched, a Green Deal Advice Report was required to ensure a minimum level of insulation had been installed. As of 24 March 2016, this is no longer required.

Case study: NEDO

The NEDO Smart Community Manchester project is the UK’s largest trial of smart heat pumps, and will see air-source heat pumps installed into 600 council-owned properties in Greater Manchester, along with an integrated IT platform to monitor energy savings. The £20m project is primarily funded by the Japanese government’s New Energy and Industrial Technology Development Organisation (NEDO), and is being carried out in partnership with the UK government. Other consortium partners include: Northwards Housing, Wigan and Leigh Homes, Six Town Housing, Greater Manchester Combined Authority, Electricity North West, Hitachi, Daikin Industries and Mizuho Bank. The project is also monitoring demand-side response, to balance grid demand and supply while keeping homes warm and comfortable for residents. This involves setting up internet provision in each home to enable the system to be remotely managed and monitored over the two-year trial period. Residents also receive a tablet with integrated software to help them manage and understand their energy use and inform them of the demand response events.

One resident involved in the scheme is Deborah Ward, who lives in a two-storey, three-bedroom mid-terrace home owned by Northwards Housing. In November 2014, her traditional gas boiler heating system was replaced by a Daikin hybrid heating unit, as well as larger radiators to maximise the system’s efficiency. The house also has a 2.5KW PV system, installed in February 2012. Before the installation, Ward spent about £11 on electricity and £15 on gas each week, equivalent to £1,352 over the year. In the first 12 months with the hybrid system, she spent £1,015, equivalent to £13.30 on electricity and £6.22 on gas per week, giving an estimated annual saving of £337.

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 23 SEPTEMBER 2016

Privacy policy

Information you supply to UBM Information Ltd may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. UBM Information Ltd may send updates about ��ɫ����TV CPD and other relevant UBM products and services. By providing your email address you consent to being contacted by email by UBM Information Ltd or other third parties. If at any time you no longer wish to receive anything from UBM Information Ltd or to have your data made available to third parties, contact the Data Protection Coordinator, UBM Information Ltd, FREEPOST LON 15637, Tonbridge, TN9 1BR, Freephone 0800 279 0357 or email ubmidpa@ubm.com. View our full privacy policy at

No comments yet