The latest in our CPD series examines the applications and benefits of OSB wood-based panels, as well as the various standards governing their use. This module is sponsored by Coillte

How to take this module

The free continuing professional development distance learning programme from ��ɫ����TV is open to anyone who wants to develop and improve their professional knowledge. These modules can contribute towards annual CPD activity and help you to maintain membership of professional institutions and bodies.

To take this module, read the technical article above and click through to the multiple-choice questionnaire.

Once taken you will receive your results and if you successfully pass you will be automatically issued with a certificate to print for your records. This module will contribute one hour towards your CPD obligations.

DEADLINE: 11 JULY 2014.

INTRODUCTION

Oriented strand board (OSB) is an engineered wood-based panel. Unlike plywood, which is built up from thin layers of wood veneer, OSB consists of strands of wood. These are bonded and arranged in a three-tier structure, with the strands in the outer layers oriented in the same direction as the panel length, and those in the core layer at right angles to it. The result is a solid panel with no core gaps that will not delaminate under normal use. This structure gives OSB a great deal of strength, which means it can be used in a variety of applications, from furniture to house construction.

METHOD OF MANUFACTURE

The species used in OSB are predominantly softwoods, such as spruce and pine. The first stage of manufacture is to debark and wash the logs. These are then placed lengthwise on a conveyor belt where they are shredded in the direction of the grain. The strands produced are typically about 100mm along the grain and 5-50mm across.

The wood flakes are then dried and blended with exterior-grade resin and wax. Common resin types include phenol formaldehyde, melamine-fortified urea formaldehyde (MUF) or isocyanate (PMDI), all of which are moisture-resistant binders. In Europe, it is common to use a combination of binders - typically PMDI in the core and MUF in the face layers. This has the advantage of reducing the duration of the press cycle required while imparting a bright appearance to the surface of the panel.

Once the strands are coated with binder, they are pressed into a mat. The flakes are arranged in three layers on a continuous belt, with the core layer at right angles to the outer layers. They are then compressed under intense heat and pressure into a rigid, high-quality structural panel. Orientation of the strands in this way distributes the strength, stiffness and spanning capacity of the finished OSB panels, which are approximately twice as strong in the length (major axis) as in the width (minor axis).

STANDARDS AND CERTIFICATION

EN 300: Oriented Strand Boards (OSB) - definitions, classification and specifications

EN 300 is the key European standard governing the specification of OSB panels. It includes a classification system that defines four grades of OSB in terms of their mechanical performance and relative resistance to moisture. These are:

- OSB1: General purpose boards and boards for interior fitments (including furniture) for use in dry conditions

- OSB2: Load-bearing boards for use in dry conditions

- OSB3: Load-bearing boards for use in humid conditions

- OSB4: Heavy-duty load-bearing boards for use in humid conditions.

EN 13986: Wood-based panels for use in construction - characteristics, evaluation of conformity and marking

This standard is a technical specification for wood-based panels which implements the provisions of the Construction Products Regulation. It outlines the different classes of panel that can be used in structural applications and gives guidance on the various performance specifications required. OSB must demonstrate conformity with EN 13986 in order to carry a CE mark.

EN 1995-1-1: Design of timber structures

The European standard EN 1995-1-1, also known as Eurocode 5, assigns a service class to wood-based structures, which reflects the conditions to which they are exposed. According to this standard, OSB2 is typically used for service class 1 - which includes internal fixings and fasteners protected from damp and cold. OSB3, meanwhile, is used for both service classes 1 and 2 - which includes the fixing of sheathing, battens and so on that are outside the thermal insulation but not directly exposed to weather. The objective of Eurocode 5 is to set performance criteria for CE marking.

BS 8103-3 Structural design of low-rise buildings. Code of practice for timber floors and roofs for housing

BS 8103-3 provides “deemed to satisfy” tables and other structural design guidance to determine the thickness, type and any limitations of OSB components for floors and roofs of dwellings. A structural engineer should be employed where the building falls outside the scope of this part of BS 8103.

British Board of Agrément (BBA) certification

OSB3 products that are certified by the BBA are permitted for structural use by UK housing warranty provider NHBC.

Forest Stewardship Council (FSC) Chain of Custody certification

This confirms the use of sustainable sources of timber throughout the manufacturing, processing, sales and distribution processes.

APPLICATIONS OF OSB

Due to its inherent strength (see below), OSB is particularly suitable for load-bearing applications in construction but it also has a wide range of other applications.

OSB2, which is suitable for dry conditions, has a number of structural and non-structural applications, including furniture, packaging, pallet tops, garden sheds, boarding-up and van fit-outs.

OSB3 is suitable for a range of internal and protected external uses, including roofing, sarking, flooring, site hoarding and sheathing for external walls, party walls, internal walls and partitions, spandrel (gable) panels, warm walls, reverse walls and structural insulated panels.

In structural applications, it is important that the service class of the proposed structure is identified and the correct type of OSB is specified. As well as conditions in service, consideration must also be given to the construction phase, where there may often be high levels of moisture or humidity.

It is also important to note that OSB with enhanced moisture resistance (OSB3 or 4) is not waterproof. The term “moisture-resistant” applies to the adhesive binder, which will not break down in the presence of moisture. Physical wetting of all grades of OSB should be avoided unless the surface is protected for external use.

BENEFITS OF OSB

OSB has a number of advantages over other wood-based products. These include:

Mechanical properties

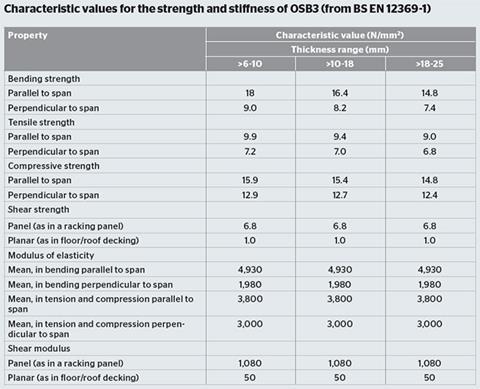

The key advantage of OSB is its mechanical performance, which is directly related to the geometry of the strands and their orientation within the panel. BS EN 12369-1 gives characteristic values for the strength and stiffness of OSB3. These are shown in the table above.

OSB contains no knotholes, core voids or points of weakness. Due to its multi-strand construction, it is not subject to delamination or blistering, as can be found on low-quality plywood.

Appearance

OSB varies in colour from a light straw to a medium brown depending on the wood species used, resin system adopted and pressing conditions employed. Factory-applied finishes can be used to give OSB a uniform appearance, as well as weather protetion, and further decorative finishes may be applied directly.

Sustainability

OSB has a number of sustainability benefits over alternative products. No tropical hardwoods are used in its manufacture and producers such as Coillte use only wood sourced from European FSC-certified sources. This is therefore located close to its market and not subject to excessive transportation. Moreover, OSB uses wood selectively removed for the purpose of forest thinning and small-diameter wood from fast-growing species such as spruce and pine.

OSB’s strong sustainability credentials are reflected in its performance in the BRE Green Guide to Specification. This provides designers and specifiers with robust information to assist decision-making by translating numerical lifecycle assessment data into a simple A+ to E scale of environmental ratings. Numerous examples are given in the guide where OSB3 contributes to an overall summary rating of A and A+.

OSB3 that has no formaldehyde added during manufacture, due to the use of specialist resin, can also be awarded the maximum available credits in the volatile organic compounds section of the BREEAM environmental rating system.

A guide published by Greenpeace in August 2008, titled “Setting a New Standard: Alternatives to Unsustainable Plywood in the UK Construction Industry”, has cited FSC-certified OSB as one of the most environmentally sound alternatives to non-FSC-certified plywood.

Fire resistance

Concerns regarding arson attacks on large timber-frame construction sites have resulted in renewed focus on the flame-retardant properties of timber and new test methods defined by the Structural Timber Association to determine performance. Flame retardance can be achieved through on-site or post-production treatment of wood panels, lamination of protective finishes onto the surface, and so on. However, in some cases this can lead to the panel becoming brittle, and the lamination of different materials onto the panel surface can make cutting and working of the panel more difficult.

OSBs such as SmartPly FR or FR Build introduce a non-toxic fire retardant during the manufacturing process of the wood panel. This ensures that flame-retardant properties extend throughout the panel, which means that cut edges present no problem and it is easy to cut and fix using normal woodworking tools. Moreover, as the additive is introduced during manufacture, the panels can be CE marked at source.

Thermal performance

OSB3 used for wall sheathing can have a positive effect on the thermal performance of framed walls. The sheathing can help to ensure the specified performance of insulation materials as it encloses and supports the insulation, thereby helping to prevent thermal bridging and thermal looping. The use of OSB3 in Passivhaus and low-energy framed buildings is increasingly popular due to its natural ability to resist the passage of air (not to be confused with water vapour permeability).

LABELLING

As design values can vary between manufacturers, it is important to ensure that the panels specified by the designer are those used on site. All panels should be clearly marked with the following information:

- Major axis (length of panel, arrows to indicate the direction of laying)

- Production identification number

- Product certification mark (such as BBA)

- CE marking

- Manufacturer’s name / logo

- Notified body identification number

- Quality certification (EN 300, EN 13986)

- Panel type (for example, OSB3)

- Thickness (for example, 18mm)

- Formaldehyde class (for example, E1)

- Additional marking for ease of reference (for example, 2+ structural)

- FSC certification.

How to take this module

The free continuing professional development distance learning programme from ��ɫ����TV is open to anyone who wants to develop and improve their professional knowledge. These modules can contribute towards annual CPD activity and help you to maintain membership of professional institutions and bodies.

To take this module, read the technical article above and click through to the multiple-choice questionnaire.

Once taken you will receive your results and if you successfully pass you will be automatically issued with a certificate to print for your records. This module will contribute one hour towards your CPD obligations.

DEADLINE: 11 JULY 2014.

Privacy policy

Information you supply to UBM Information Ltd may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. UBM Information Ltd may send updates about ��ɫ����TV CPD and other relevant UBM products and services. By providing your email address you consent to being contacted by email by UBM Information Ltd or other third parties. If at any time you no longer wish to receive anything from UBM Information Ltd or to have your data made available to third parties, contact the Data Protection Coordinator, UBM Information Ltd, FREEPOST LON 15637, Tonbridge, TN9 1BR, Freephone 0800 279 0357 or email ubmidpa@ubm.com. View our full privacy policy at

No comments yet