The latest in our CPD series introduces Environmental Product Declarations. This module is sponsored by Marley Eternit

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 17 AUGUST 2015

INTRODUCTION

An Environmental Product Declaration assesses the environmental impacts of a product through its entire lifecycle, taking into consideration the manufacturing, transportation, assembly, use, removal and recycling or disposal of the product. It is similar to a Life Cycle Assessment (LCA), but whereas an LCA can be produced by a manufacturer – which may make favourable assumptions about aspects such as the longevity of a product – an EPD is independently verified.

Although EPDs are applied in several European countries, covering all types of goods and services, they are not mandatory in the UK. However, they are used increasingly in building rating schemes such as BREEAM, which has led many manufacturers to provide EPDs for their materials. There are now about 2,000 EPDs available across Europe, and the system is likely to grow in importance as more architects and specifiers use it to compare the environmental properties of different products.

This CPD sets out the benefits and key elements of an EPD, and outlines how architects and specifiers should use them.

HOW EPDs WORK

An EPD provides all the relevant environmental information about a product for its whole lifecycle in accordance with the international standard BS EN ISO 14025 (Type III Environmental Declarations).

Manufacturers work with an independent programme operator, such as IBU in Germany, to ensure that products are assessed in a consistent manner and the data is unbiased and factual. To achieve this, each EPD in any given product category is governed by the same Product Category Rules (PCR), controlled by the European standard EN 15804.

Both generic and product-specific EPDs are currently available. Generic EPDs are usually produced by trade associations and cover many common construction materials – for example, there is one for UK cement and one for bricks. Generic EPDs are useful for smaller manufacturers as it would be expensive for them to produce their own declarations. A product-specific EPD relates to a particular product or range created by a single manufacturer, and takes into consideration distinct characteristics such as the supply chain and production methods used by that company.

EPDs for construction products tend to be modular. This means an EPD for cement could be used with an EPD for aggregate to produce an EPD for concrete.

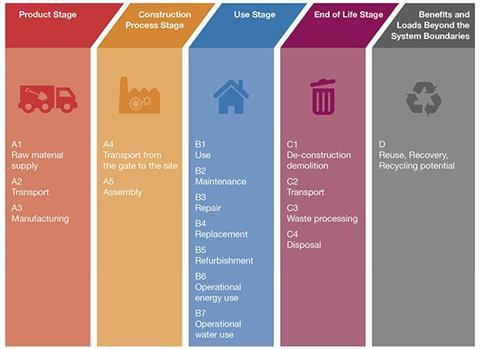

Within an EPD, information is split into 17 distinct categories, which in turn are grouped into five key areas, as follows:

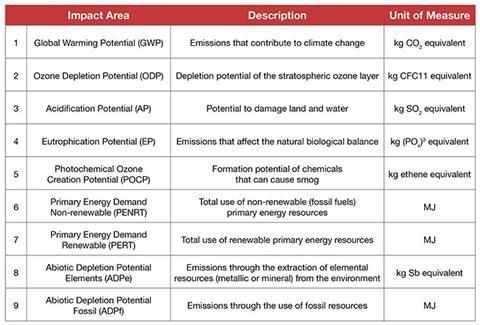

For each lifecycle stage, the EPD provides an assessment of environmental impact in the following nine areas:

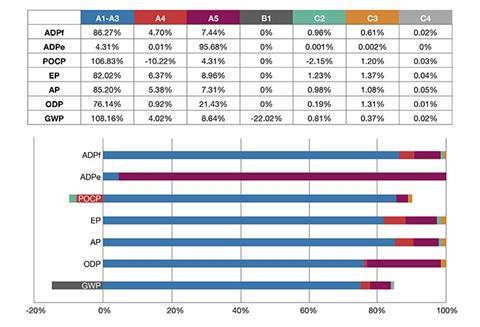

Manufacturers, specifiers and other construction professionals can then assess which lifecycle stages contribute most to the environmental impact of the product. Below is an example of an assessment for a fibre cement slate product, across all nine impacts and all 17 lifecycle stages:

For products that do not consume energy in use, such as fibre-cement products, the impact is likely to be heavily skewed towards raw materials and manufacturing. On the other hand, products that consume energy in use, such as a washing machine, will have a higher impact during the use stage.

BENEFITS AND POTENTIAL ISSUES

The key benefit of EPDs is that they allow architects and specifiers to compare products in terms of their whole-life sustainability – an increasingly important consideration as clients demand compliance with certification schemes such as BREEAM and LEED. There are software packages that can be used in conjunction with EPDs to analyse the impact of operational, embodied and long-term carbon (see below).

However, this will only be truly possible when there is a greater range of EPDs available – currently only about 2,000 of the millions of the products manufactured in Europe are covered by the system.

There is also a common misconception that an EPD is a sustainable seal of approval. It is not. Like a food nutrition label, an EPD simply reports the environmental impact of a product – even radioactive waste could generate an EPD.

An additional benefit of EPDs is that they can be used by manufacturers themselves to identify areas that need improvement, to challenge processes and communicate improvements to customers.

USING EPDs TO DESIGN AND BUILD

To compare the environmental impact of products with an EPD, architects and specifiers need to ensure that EPDs have been completed to the same Product Category Rules and that assessments have been carried out using the same declared unit (for example, 1m2 of a roof system) and corresponding lifecycle stages.

To make the task of interpreting the data in an EPD simpler, there are a number of tools available including GreenSpace Live’s Rapiere system and IES’s IMPACT compliant suite within its VE software, based on the BRE protocol for LCAs. These tools are designed to enable an architect to make comparisons at building level or between material choices. However, it is important to check which EPDs a tool is able to compare, as many only accept EPDs from certain data sources.

The integration of LCAs into BIM is also becoming a reality with the introduction of Tally, a software application for Revit that calculates the environmental impact of building materials. While it uses only American generic EPD data, it is the only application to be fully integrated into Revit, providing architects, engineers and building professionals with insight into how materials-related decisions made during design influence a building’s overall ecological footprint.

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 17 AUGUST 2015

Privacy policy

Information you supply to UBM Information Ltd may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. UBM Information Ltd may send updates about ��ɫ����TV CPD and other relevant UBM products and services. By providing your email address you consent to being contacted by email by UBM Information Ltd or other third parties. If at any time you no longer wish to receive anything from UBM Information Ltd or to have your data made available to third parties, contact the Data Protection Coordinator, UBM Information Ltd, FREEPOST LON 15637, Tonbridge, TN9 1BR, Freephone 0800 279 0357 or email ubmidpa@ubm.com. View our full privacy policy at

No comments yet