Sponsored by Ryno, this module takes a deep dive into balcony and terrace flooring, looking at the regulations and standards which govern design, alongside the common challenges and best practices

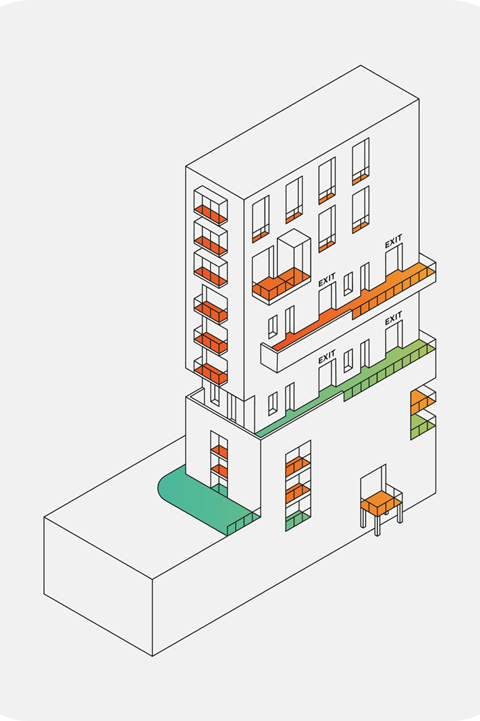

The biggest difference between balconies and terraces is that balconies form part of the external facade under the building regulations as a specified attachment. Balconies can be protruding or recessed depending on their circumstances, as detailed in BS 8579:2020. Terraces, however, will typically form the function of a roof and be over a building’s compartment.

To help bring clarity to an ever-changing industry and raise the bar of compliance for balcony and terrace flooring, this module will take a closer look at the regulations and considerations that apply to both, alongside the specific technical standards that address each.

Learning objectives

- Gain knowledge of UK building regulations and best practices relating to balcony and terrace flooring

- Understand how to integrate planters and furniture into external flooring systems

- Be able to select the most appropriate flooring system for your project

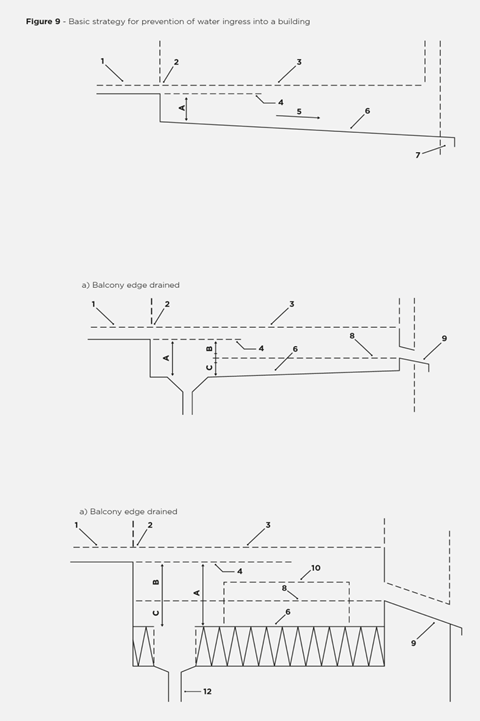

Drainage duty

A priority for balcony and terrace flooring is ensuring adequate drainage is in place to achieve regulatory compliance. For both balconies and terraces, a minimum of 75mm from the underside of the threshold (or ingress level) to the waterproofing or drainage layer is needed to prevent water ingress into the building.

The BS 8579:2020 sets out that the gaps between the pavers and decking should be incorporated into the design to allow water drainage. It recommends that there should be a maximum of 8mm gap between the pavers or deck boards to allow for effective water flow while minimising the risk of discomfort to wheelchair users. The industry norm for porcelain tiles is between 2-4mm due to the accurate sizing of the units. For concrete and natural stone, the industry norm is 4-6mm, and for between decking, 6-8mm gaps are used.

A more detailed breakdown can be found in section 15 of BS 8579:2020.

Perimeter detailing

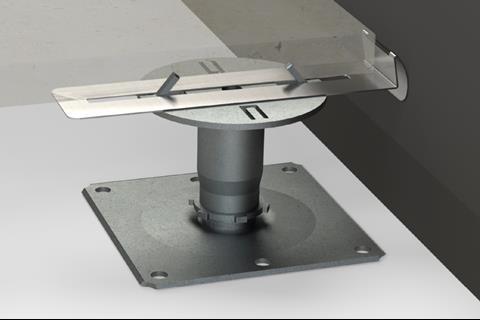

Around the perimeter of balconies or terraces, the BS 8579:2020 sets out the need to maintain a 10-12mm perimeter gap to facilitate good drainage of the floor surface. The stability of a paving and pedestal system is largely down to the tight installation of the pavers on the head of the pedestal. If the pavers are able to move on the head of the pedestal then over time the pavers and pedestals can move and become loose or unstable. This also becomes important at the perimeter. Leaving a 10-12mm perimeter gap with nothing to maintain it, can lead to the pavers moving. This is why it is key to install an edge spring clip on each of the perimeter pedestals. The edge spring clip maintains the required gap at the edge but also stops the pavers from moving out to the edges. This maintains the uniform lines and longevity of the system.

For a flooring system’s longevity, including edge spring clips is one of the most important aspects of the design. The 10mm-12mm perimeter gap installed without restraint will result in movement over time, causing the gaps to open and create a critical health and safety hazard.

One of the most common causes of failure for paving on pedestals is not including edge spring clips. An edge spring clip is required to maintain the perimeter gap. The spring adds tension to the paving by pushing the material to the centre, maintaining the uniform gaps between the pavers.

Commonly overlooked as an insignificant component, edge spring clips can make or break a successful paving design when using paving on pedestals.

Pendulum test value

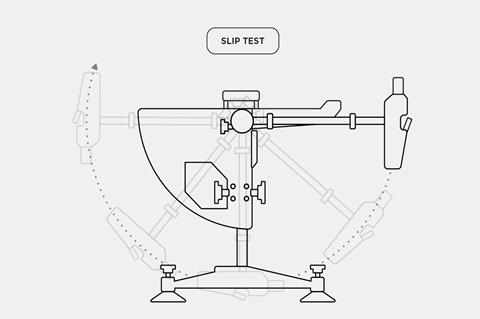

Both balconies and terraces must have a surface that meets the required slip resistance.

In the UK, floor slip resistance is measured using a pendulum apparatus. This is known as the pendulum test method in BS EN 16165:2021 Annex C (previously BS 7976:2002), and the results are given as a pendulum test value (PTV). The results are classified into high, medium, and low risk of slip, with a 36PTV being the minimum requirement for low slip potential for external floor surfaces.

The surface must be tested with a 96 slider (rubber) which simulates a shod foot (someone wearing shoes); an additional test using a 55 slider can be carried out for areas where users will be without footwear. The pendulum test should be carried out in three directions across the surface, and the lowest mean value is taken as the rating for slip resistance. It is important to ensure that this is stated in the report.

Some manufacturers will state the slip resistance of their flooring products as an R-value, such as R11 for external use. This is tested to the European Standard DIN 51130, which has no direct correlation to a PTV result and is not used in the UK. To maintain compliance, designers must specify the slip resistance as a measure of PTV to BS EN 16165:2021 Annex C.

For terraces and podiums, common challenges occur in levels across an area, resulting in ramps being specified. There is a requirement for a higher level of slip resistance on a ramp to achieve the same degree of safety. A target PTV on a slope is calculated using a formula provided by the UK Slip Resistance Group.

Strong winds

Wind uplift occurs when strong winds encounter a building and are forced up and over it. This accelerates the wind and creates a pocket of negative pressure above horizontal surfaces, such as balconies and terraces. Every building experiences the effect of wind differently, which can change throughout the building’s lifetime as the surrounding landscape evolves.

Wind uplift is increasingly recognised as a serious consideration at the design stage as buildings in the urban environment continue to grow in height. Architects, designers and specifiers must recognise the need to carry out a wind load assessment early in the design stage to mitigate the risks as much as practicable.

There is no standard approach to mitigating wind uplift. Instead, the emphasis is on calculations, with each project needing to be assessed on an individual basis. However, mechanical fixings and increasing the dead load beyond the uplift force are two common methods for overcoming wind uplift.

Designs must consider the potential for wind lift and ensure the pavers cannot be dislodged or lifted. For balconies with fixed decking, the risk comes when furniture can be lifted by the force created by wind. Providing adequate tie-down points or anchors to secure furniture is advised within BS 8579:2020.

Inclusive design

Accessibility is vital when designing a space to be inclusive of all users, with level thresholds being one way to increase accessibility through a doorway onto an external space.

Designers must consider that any remediation or refurbishment works focused on accessibility must acknowledge the existing balustrade height to ensure that the finished flooring level sits 1,100mm below the top of the balustrade. The National House ��ɫ����TV Council includes this as standard for its developments, with further guidance on level thresholds provided in Approved Document M.

Planet first

When specifying flooring material for a balcony or terrace, the sustainable credentials of the product should be carefully considered. With several material choices on the market, finding the right one for your project can be challenging. While concrete is still having its moment within the industry, two options that could be considered for their sustainable credentials are aluminium and porcelain.

Aluminium is 100% recyclable, with nearly 75% of all aluminium ever manufactured still in use today, making it a sustainable choice for both balcony and terrace flooring. Porcelain is also an environmentally friendly material, recognised as having the longest lifetime potential of any building finish. Produced with mostly recycled and recyclable materials, such as natural rocks and minerals, it is another option for projects looking to reduce their environmental impact.

Maintenance

Like all flooring, paving and decking require maintenance. Aluminium and porcelain are non-porous materials and therefore do not retain moisture for mould and algae to grow, meaning a wash-down with soapy water is all that is required.

Traditional timber decking, however, requires a lot more maintenance throughout the year to prevent rot, mould and algae from growing and reducing the lifespan of the deck. Concrete pavers, while they do not require as much maintenance as a timber deck, do retain moisture and therefore need to be maintained to stop them from becoming slippery if mould forms.

Aluminium does not rust, so the deck and joist supports do not need treating.

External facade

Under the ��ɫ����TV Regulations, balconies are classed as part of the external facade as a specified attachment.

Following amendments to Approved Document B in June 2022, balconies on a relevant building under Regulation 7 and balconies on buildings for residential purposes that are 11m or more in height are required to achieve a minimum fire classification of A2-s1, d0, under EN 13501-1:2018.

In January 2020, the Department for Levelling Up, Housing and Communities (previously the Ministry of Housing, Communities and Local Government) released Advice Note 22, which states that buildings of all heights should not contribute to rapid fire spread. While regulations state that a relevant building needs to meet a minimum of A2-s1, d0, many insurers are now providing better insurance premiums for buildings that meet a higher level of compliance regardless of height.

It is often argued that decking should be classified as a flooring product. However, the third part of the fire classification relates to the amount of flaming droplets emitted within the first 10 minutes of exposure to fire. Flaming droplets are a big factor on a facade due to the potential spread of fire across the building – a factor not considered in a flooring test.

Along with fire regulations and slip resistance, it is important, when specifying a decking or paving system for a balcony or terrace, that designers know what loadings they need to be working with. This can be found in Eurocode 1 .

Balconies fall under category A in tables 6.1 and 6.2 of EN 1991-1-1:2002. This means they are required to meet a standard design load of 2.5kN/m2 (uniformly distributed load) and 2.0kN concentrated load. Writing these numbers in your specification will ensure that products meet the design standard set out.

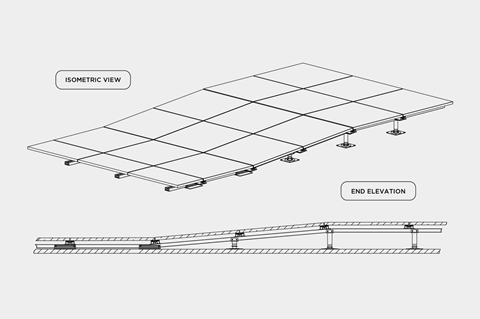

The function of a roof

There are a variety of pedestals available, from self-levelling and fixed head to stackable pedestals and a rail system for increased support or to mix up the paving layouts. Projects can also specify localised areas of bonded paving integrated with free-draining paving for smaller tiles which require additional support.

Terraces typically form the function of a roof. Therefore terraces and podiums should meet a minimum of Broof(t4) fire classification per BS EN 13501-5:2018.

BROOF(t4) is the highest classification and is unrestricted in its use on a roof. The roofing classification looks at the penetration of fire through the roof build-up and can allow for elements of material made from Euroclass E fire rating. This means that if tested to meet BROOF(t4), plastic pedestals can be used on roof terraces which provides several benefits including reducing the load on the roof and providing cost savings.

The European Commission Decision 2000/553/EC provides a list of products that can be considered to fulfil all of the requirements without the need for testing. BS 8579:2020 also sets out further clarification on roof coverings for terraces.

Due to the current climate following the Grenfell Tower tragedy, it is common to go beyond compliance and work with non-combustible pedestals on all relevant buildings.

Concerning structural calculations, they should be made by looking at the intended purpose of the terrace alongside tables 6.1 and 6.2 in BS EN 1991-1-1:2002. The amount of footfall and vehicle requirements can dictate the required support system as they have different capabilities.

It is vital to provide all loading calculations to the manufacturer of the paving, decking and support systems to ensure that they can take any increased loads. Working to the minimum heights of pedestals can cause complications at the installation stage of the development as often the tolerances on site are larger than what has been specified, making the build-up hard to achieve.

It is recommended to leave a minimum of 150mm above the insulation or waterproofing layers to provide adequate space for the substructure. Ensuring you have the void height, correct pedestal spacing and insulation strength are essential components to achieving a compliant roof terrace.

Planning planters

Planters are a great way to incorporate green space into terraces and connect people with nature. This has a number of benefits, such as improved wellbeing, reduced stress, and increased biodiversity.

When designing planters for a roof terrace or podium space, there are several key considerations. The first is the strength of the waterproofing and insulation below the planter. If the insulation has a low compressive strength, additional measures may be needed to distribute the load more evenly. Having planters integrated with the paving support system also makes it easier to support small cuts of paving.

The team designing the insulation specification must collaborate with the landscape architect/designer to ensure the correct coordination of the terrace space.

Ramps required

Approved Documents K and M provide guidance on the design of ramps and steps, as well as consideration for those with impaired or limited mobility. Regulations state:

- Increased PTV value is required on ramps to reduce the risk of slipping.

- Pedestals alone are not a suitable support type to create a ramp.

- Rail systems are commonly used to provide the required support due to its lattice framework

- Handrails may need to be included.

On podiums and terraces, it is common for there to be changes in the finished floor level, resulting in ramps being required. When using raised flooring systems, it is not suitable to use pedestals to create the ramp as they do not provide the required lateral support. It is important to use a rail system to create a ramp and extend it a minimum of 1.5m at the head and foot of the ramp to ensure a smooth transition to the level surface.

As discussed earlier, a greater level of slip resistance is required on a ramp. If aluminium decking has been specified, a higher slip-resistant deck board will be needed. Various grades of coating can also increase the slip resistance.

Please fill out the form below to complete the module and receive your certificate:

No comments yet