At the base of Grenfell Tower sits a state-of-the-art secondary school â now lying empty, in the wake of the tragic fire. The Education and Skills Funding Agency had a single summer to find Kensington Aldridge Academyâs 960 pupils a temporary new home â and pulled it off in nine weeks, with the help of Mace and Portakabin.

On 18 September, barely 13 weeks after the school was closed by the devastating fire at Grenfell Tower, the new Kensington Aldridge Academy, known as KAA2, opened its doors to students. The temporary school for 960 pupils has been built on the site of a former Ministry of Defence cavalry exercise ground â in just nine weeks from site set-up to occupation. âWhat has been achieved here is unprecedented,â says Phoebe Leach of Mace, lead technical adviser on the project.

Until the terrible events of 14 June, the school was based in a state-of-the art, ÂŁ26m home at the foot of Grenfell Tower. Its original building still stands next to the charred shell of the 24-storey tower block in which 80 people are believed to have died. While it escaped serious damage, it was obvious from the outset that the schoolâs proximity to the tower made it unsuitable for use until the forensic teams finish their work and the structure is wrapped or demolished. Temporary accommodation was needed â and fast.

Here we talk to the key people to find out how the team delivered the fastest school ever built, from acquiring a suitable site and opting for a modular system, to using off-site fit-out and even fast-tracking the utilities connections.

The fastest school ever built

âThe school had to be relocated, so we needed to provide accommodation for the start of the September term,â says Sue Archer, project director for the Education and Skills Funding Agency (ESFA), the projectâs client.

Archer was assigned to head the project team a week after the fire, on 21 June. The day after her appointment, she enlisted Mace as technical adviser to the project. She also instructed LocatED, the property acquisition arm of the ESFA, to search the area around the tower for premises that would be suitable for use as a temporary school; its remit was âto consider any building or site, including vacant office blocks, that could be quickly converted into a temporary secondary schoolâ, she says.

Two days after being given the assignment, Archer had put together a budget and a programme for the scheme and was visiting potential sites. âWe did an analysis of all the potential premises to find the least problematic,â she says.

One of the initially favoured options was for KAA to be temporarily relocated to classrooms placed on the playing fields of the nearby Burlington Danes Academy. However: âWhen we visited the site, it was obvious that it was far from ideal: it was landlocked, which would have made it difficult to install the cabins, there were no utilities close to the site, and the ground was boggy,â explains Archer. This option also would have prevented Burlington Danes using its sports facilities.

Fortunately, while on the visit, a conversation with Burlington Danesâ head teacher, Michael Ribton, raised the possibility of a far better solution. âHe said âHave you thought about using the parade ground next door?ââ Archer recalls.

Adjacent to Burlington Danes was a large area of level ground that had been used by the MoD to exercise horse and gun-carriage teams. Archer says: âI went there, I took some photos, then I rang LocatED and, using Google Maps, I said: âFind out who owns the land that Iâm stood on.ââ

The site, which was about a 20-minute walk from Grenfell Tower, was found to be owned under a tripartite agreement between the MoD, the London Borough of Hammersmith and Fulham and the Wormwood Scrubs Charitable Trust. âBy the end of the day LocatED had rung all three landowners and obtained their indicative consent for the use of the site,â says Archer. It took a few days to formalise the agreement, but the end result was the ESFA has a licence from Hammersmith and Fulham council to occupy the site for just over a year.

Along with finding a site, the other main task was to appoint a contractor capable of building the temporary school in the remaining 11 weeks. Maceâs Leach says the project teamâs instinct was to lease a modular solution, with Portakabin as supplier of choice. Nick Griffin, Portakabinâs project sponsor, says: âWe took on the project at our busiest time of year and in the busiest summer we have ever had, so to make it happen meant assigning a team in our York plant to the project and then backfilling their places by bringing in people from our plants in other parts of the country.â Four days after the site had been found, Portakabin was appointed as the projectâs main contractor.

Watch a time lapse video of how the project was completed in nine weeks

Project Team

Client: Education and Skills Funding Agency

Technical adviser to ESFA: Mace

Structural engineer: RNP

Main contractor/module manufacturer: Portakabin

șĂÉ«ÏÈÉúTV services: Portakabin șĂÉ«ÏÈÉúTV Services

Groundworks: Portakabin Total Solutions

Fast-track design process

Almost immediately Portakabin started design workshops. David Benson, the academyâs head teacher, was determined the temporary school would be a like-for-like replacement, to enable teaching staff to replicate the curriculum structure. An addition would be enhanced counselling facilities to support the children following the trauma of the fire. The schedule of accommodation for the academy, which specialises in the performing arts, included: a dance studio, a drama studio, a food technology room, design technology workshops, music rooms, science laboratories and art rooms.

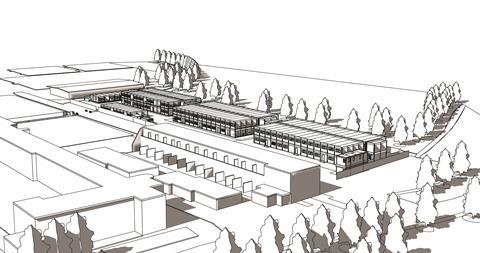

Portakabinâs design solution is based on dividing the accommodation into three main two-storey blocks: Block A, for general teaching, Block B for the dining hall and science facilities, and Block C for specialist teaching, including food technology and IT. The site is rectangular in plan; narrow on the north-south axis, wide on the east-west. The blocks are located in a line along the siteâs east-west axis. In addition, there are three smaller, single-storey blocks clustered around the siteâs western perimeter: Block D for dance and drama, Block E for special educational needs, and Block F for reception and offices.

A week after the first workshop was held, the design had been developed to a point where the general arrangement drawings for the 7,500m2 school could be signed off to enable manufacture of the 210 modules to commence.

With the basic design established, the team moved on to detailed design. Regular co-ordination meetings were held throughout the project to facilitate communication and to resolve outstanding issues. âThe speed of decision making was like nothing else,â the ESFAâs Archer says. âWe would have design meetings where we were talking about some aspect of the scheme at one end of the table while at the other end would be the design team; by the end of the meeting a decision would have been incorporated and the revised design sent back up the table for sign-off.â

Project timeline

Barely 13 weeks after the tragic fire, the school opened its doors to students â after just four weeks of project planning and a nine-week site operation

14 June: Fire at Grenfell Tower adjacent to the school

21 June: ESFA appoint Sue Archer as project director and project manager

22 June: Mace appointed as technical adviser

23 June: ESFA locates two potential sites

27 June: Portakabin engaged

28 June: Parade ground requested as main site (with Burlington Danes Academy held in reserve)

30 June: London Borough of Hammersmith and Fulham (LBHF) and MoD consent to use of parade ground

3 July: Portakabin start design workshops

10 July: General arrangement plans signed off

12 July: Portakabin starts set-up on site

17 July: Portakabin begins groundworks

21 July: Portakabin submits șĂÉ«ÏÈÉúTV Control application to LBHF

24 July: Portakabin design workshops progress through to detail design with the teaching staff

28 July: First of the 210 modular units delivered to site

8 August: Planning application submitted

6 September: Final modules (stair pods) installed

11 September: First block handed over and FFE fit-out commences

14 September: A day ahead of schedule, teachers begin preparing classrooms

15 September: First sectional completion achieved

15 September: șĂÉ«ÏÈÉúTV Control sign off and occupation certificate issued

18 September: School takes occupation, with 780 pupils attending on first day of term

On-site and off-site

Two days after the general arrangement drawings had been signed off, Portakabin started on site. Access to the site is from the west, so all groundworks, module installation, fit-out and landscaping, from site-start on 12 July to sectional completion on 15 September, were programmed to progress across the site from east to west. âFrom a design perspective, this sequencing allowed us to work with the stakeholders on Block A to get its design frozen and into production before moving on to Block B,â explains Maceâs Leach.

To speed up on-site construction, Portakabin set out to maximise off-site fitting out. In addition to its York manufacturing plant, Portakabin marshalled modules at two of its other sites: fit-out of the modules for Block A was carried out at its Hemel Hempstead depot, while fit-out of the modules for Block C was undertaken at its Peterborough Hire Centre. Blocks D and E were manufactured and fitted out at Portakabinâs manufacturing plant in York. âSpreading the work over several sites allowed us to minimise work needed on site. Had we not maximised off-site fit-out, there would have been far too many people trying to work on the site,â says Portakabinâs Griffin.

The modules for Block B were also built in York, but fit-out of this block was carried out almost entirely on site. This was due, in part to the block incorporating the more heavily serviced science laboratories but predominately because a late design change meant that a school kitchen and dinning hall, which had initially been located in a marquee set up on the site, were relocated to Block B at the last minute.

The school is assembled from Portakabinâs Ultima modules. Blocks A and B are each assembled from 56 modules that measure 12m x 3.3m; Block C is constructed from 56 modules measuring 10m x 3.3m each. The smaller, single-storey blocks are constructed from a smaller number of the same 10m x 3.3m modules.

All of the modules were manufactured from new, either using existing blank modules from Portakabinâs hire fleet stock or built specifically for the project. âWe did have pre-existing school modules from other schools, which would have required refurbishing, so we took a decision that to be consistent and to give us total control over production weâd manufacture all modules from new,â says Griffin.

Critical to meeting the project deadline was the need to get the school connected to the utilities running along Wood Lane. The school needed a 1000kVA, high-voltage substation to be installed by UK Power Networks (UKPN). According to the ESFAâs Archer, this was a process that would ânormally take 11 months to completeâ. For this project UKPN pulled out all the stops: the initial application for the substation was submitted to UKPN on 13 July; by 25 August the substation was energised. âOne of the biggest achievements with the job was that we got UK Power Networks to site within a day, and we had power on site within six weeks,â she says.

Thames Water was equally accommodating: the order for a 90mm connection was placed on 31 July, with the connection completed by 18 August; similarly, the order to provide a connection to the foul drain was placed on 3 August and completed on 22 August.

On 28 July, just over six weeks after the fire, the first module was craned into position on Block A. An average of seven modules a day were installed, and with Portakabin working seven days a week progress was swift. Each of the three two-storey blocks were installed over a six-day period, with an additional dayâs contingency allowed before installation was scheduled for the next block.

As the project gathered momentum, so too did the size of Portakabinâs site workforce; it started out with a team of 12 operatives for site set-up and enabling, but that number steadily increased to a peak of 200 during the final week, when the furniture, fixture and equipment (FF&E) contractors were on site too. All subcontractors were appointed by Portakabin. âWe did everything on this project with the exception of connection to the utilities,â explains Griffin. âThe big advantage of this approach is that it gives us complete control over the programme and it ensures the subcontractors we use are familiar with working with modules,â he says.

In the final week of the programme Portakabinâs teams even worked through the night on two occasions to facilitate the FFE fit-out.

Final approval

KAA2 opened on time on 18 September. Although it is only temporary, the school is intended to have the look and feel of the pupilsâ permanent home, so vinyl graphics have been applied to the outside to match the sea-green panel-clad buildings of their original school. Familiarity is helped by reusing wall displays and much of the furniture from the existing school.

Planning permission for the temporary school was not submitted until 8 August, almost a month after work started on site. âThis is open land, so youâd normally struggle to get planning permission to build on it,â says Archer. However, throughout the design development the ESFAâs planning adviser has been in dialogue with the local planners to keep them abreast of the scheme.âEverybody knew what we were doing; we told them couldnât put in a planning application until August because we wouldnât have designed the building before then,â explains Archer. On 11 October, almost a month after the school opened, planning permission was finally (and unanimously) granted for the scheme. The ESFA is not yet ready to publish a figure for the cost of the temporary school.

The plan is for the temporary school to remain in use for a year. By that time, it is hoped that the original school will be ready for reoccupation, with Grenfell Tower covered and the outside spaces made safe. The licence for use of the parade ground runs for 70 weeks to allow the site to be fully decanted and to revert back to its original use. âWeâre negotiating at the moment on what weâll have to strip from the site when we leave,â says Archer. Meanwhile Mace is using its learning from the project to consider how it can better incorporate off-site manufacture into its school delivery programmes.

No comments yet