In creating the UKâs tallest build-for-rent development â Highpoint in Londonâs Elephant and Castle â flexibility, efficiency and speed were key concepts for contractor Mace and structural engineer AKT II

Highpoint is a pointed addition to the capitalâs skyline. It is tall; at 47 storeys it rises high above the bustling streets and neighbouring towers that form the fast-evolving streetscape of Londonâs Elephant and Castle. It is also noticeably more slender than many of its neighbours; and it has a distinctive four-limbed crown. But what makes this scheme so different, is that it has been designed and built specifically for the private rented sector. When it opens in January 2018, it will be the tallest built-for-rent development in the country.

Like any residential scheme the cost principles of optimising the lettable area, getting the number and right mix of apartments remain true for private rented sector (PRS) â only more so. Design-and-build contractor Mace and its structural engineer AKT II have worked hard to develop an efficient design to maximise lettable area and optimise flexibility of the floor plates.The team has also developed an innovative structural solution and standardised as much as possible to improve efficiency, speed up construction and minimise costs. âThis scheme was about starting with a blank sheet of paper and saying âhow can we design one of the tallest residential towers in the capital to be built quickly, efficiently and leanlyâ,â says Rob Partridge, a director at AKT II.

Surprisingly, the design concept dates back 13 years to 2004, when AKT II first worked on the scheme with architect Rogers Stirk Harbour + Partners for developer First Base, with backing from government regeneration agency English Partnerships. Together architect and engineer set out to design a residential tower with apartments for sale and rent that would be quick and efficient to build, with open floor plates to allow the developer flexibility on how they were configured. It is a testimony to the robustness of the solution developed then that it is still the best solution for PRS over a decade later.

Compact

The site defined the buildingâs compact footprint, so the design team set out to make its concrete core as small as possible in order to maximise lettable space on the floor plates. A solution was developed with a core measuring just 10m x 10m, big enough to accommodate the buildingâs four lifts, a staircase and the service risers but little else.

The problem, however, with shrinking the buildingâs core is that, in addition to facilitating the vertical movement of people, structurally the core provides lateral stiffness to the tower. The smaller the core, the less stiff the tower and the more likely it is to sway in the wind. âA small core means providing stability is more of a problem,â explains Partridge.

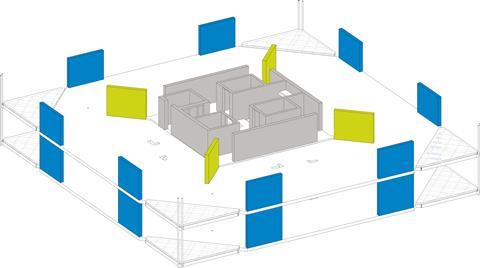

To build stiffness into the tower Partridge added a rigid perimeter structure with the addition of prefabricated reinforced concrete panels to the perimeter of the 26m x 26m floorplates. Two panels are incorporated into the facade on each elevation.

In the super-slender towers of New York and Chicago the core is tied to the perimeter every 12 floors or so by giant beams, to create a single stiff structure. âInstead of just the core taking lateral loads, by mobilising the perimeter structure the whole volume of the tower works to provide stability,â explains Partridge. The downside of this solution is that the outrigger beams are so large that the floors on which they are located are generally only suitable for use as plant rooms.

Rather than lose valuable lettable space, for Highpoint AKT IIâs innovative structural solution has been to split the giant beams into thin horizontal slices by designing each of the towerâs 250mm-thick reinforced concrete floor plates to act as a mini-outrigger. The floors link the core to the precast concrete perimeter panels.

Additional lateral stiffness is provided by the towerâs internal structure of four diagonal reinforced concrete walls. These buttress the central core, but are separated from it by the circulation corridor that rings the core. The walls are positioned on a line from the corner of the towerâs core to the furthermost corner of the towerâs corner balconies, a positioning that ensures they are integrated into the diagonal separating walls between apartments.

âWe used walls, as opposed to columns, to reduce the number of components internally because you need fewer of them and the walls also provide additional lateral stiffness,â explains Partridge.

Carefully detailed reinforcement design ensures that both the diagonal walls and the perimeter walls are tied into the floor slabs to create a homogeneous structure. âThe reason the structure is so lean is that every concrete element, and the joints between them, all work as part of the stability system in addition to resisting the vertical loads,â Partridge says.

The structural design was then further rationalised to enable all vertical structural components to be standardised so that they can be prefabricated in order to simplify construction and reduce build time. âWe had to go outside the codes because design guidance for precast walls has a limit of 12 storeys and this building has 47,â says Partridge.

The reinforced concrete facade panels are prefabricated as a single element. The diagonal wall panels are prefabricated using a twin-wall system. Twin wall enables reinforcement to be inserted between the two biscuits of concrete that form the front and back faces of the wall, after which concrete is poured the void to create a solid unit. âWe designed a solution where all components are the same dimensions, whichever floor they are on; the only difference being the amount of reinforcement they contain,â says Partridge.

The super-efficient solution has means that the floorplates have a net internal area of 477m for a gross internal area of 587m2.

Efficient

The original scheme was granted planning permission but was put on hold when the recession hit in 2008. In 2010, English Partnerships (now renamed Homes and Communities Agency) resurrected the scheme. Mace Developments submitted the winning tender with its PRS scheme funded by Realstar. Mace Construction was subsequently appointed to build the scheme under a fixed price design-and-build contract, retaining AKT II astructural engineer and employing Axis Architects as its delivery partner. Enablingworks started in November 2014. In January 2015, construction commenced.

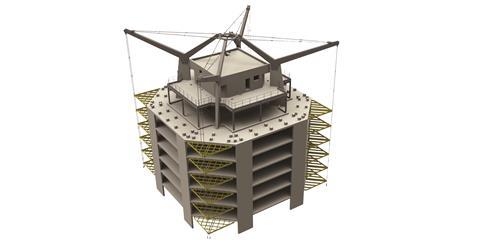

The drive to improve efficiency and speed in construction that began with the design team was continued on site. As soon as the foundations were completed, construction of the buildingâs core started. Mace worked with formwork firm Doka to adapt its Super Climber â a self-climbing jump-form rig â to configure it to cast the towerâs slender core.

This is only the second time this particular platform had been used in the UK. Its advantage is that it has in-built hydraulic jacks to raise the rig without the need of a crane, which means it can operate in wind speeds of up to 72km/hour. The rig is on two levels: the tower cranes deliver materials, including the coreâs precast concrete stairs, to the top level from where they are fed through hatches to the workers safely enclosed on the level below. âThe rig allowed us to store enough rebar on top level to construct two floors in advance of those times when high winds limited crane use,â explains Bart Lemmens, Mace senior project manager.

The core was constructed at a rate of one floor every six days. Following four floors behind, and hidden from view behind a second Doka climbing screen, were the floor-laying team. Their role was to cast the concrete floor slabs on top of the precast concrete perimeter panels and the diagonal twin wall elements. âThe driver for the use of precast was to save time, it knocked about a day per floor off the programme,â says Guy Hunt, Mace project director. âOn average we were completing one floor every six days â it would have taken nine days per floor using conventional construction,â he adds.

The Doka system includes sensors built into the floor slabs that send a text when the concrete has reached the required strength. âWith high-rise construction it is important to hit strength as quickly as possible because then we can strike the shuttering and climb the screen ready for the process to commence over again,â says Maceâs Lemmens.

As soon as the climbing screen clears a floor the buildingâs four external hoists are extended upwards to connect to the new floor so that fit-out can commence. First onto the empty floor plates are the prefabricated bathroom pods and prefabricated service cupboards. Again, the design has been rationalised so that there are only three models of bathroom pod: a right-hand model, a left-hand model and an en-suite model. As soon as the pods have been wheeled into position, the cladding team moves in.

Cladding contractor Yuanda was responsible for installation of the facades and for the giant yellow triangular steel balconies. The balconies have been designed to be self-supporting so that they can be installed without the need for temporary props on site, simplifying construction. However, from the edge of the floorplate to the tip of the balcony is a 4m cantilever, the length of which means that without some form of restraint the balconies would be very springy indeed. AKT IIâs solution is to link the tips of the balconies together vertically using Macalloy rods and then to tether the Macalloy rod to one of the arms of the buildingâs structural crown to help damp any movement (see below).

Once the weather protection was in place, the fit-out teams then began their race up the tower. There are 44 floors of eight apartments to fit out. To ensure fit-out went smoothly, Mace had a trial apartment built off site to iron out any snags before the race commenced. âRepetition is a big part of the success of this job; every floor, from floor 2 to 44 is the same,â says Hunt.

On site now, the towerâs construction is nearing completion. One of the towerâs pair of accompanying tower cranes has already disappeared, the second is due to go in the next few weeks. The race is now on to complete fit-out of the final few apartments on the upper floors. When it opens in January 2018, Highpoint will provide Canadian real estate manager Realstar with 344 units on the towerâs upper floors (floors 10-44) for private rent and housing association Peabody with 115 shared ownership apartments on its lower floors (2-9). With the UKâs housing shortage continuing, purpose-built PRS blocks may become more common â and Highpoint may prove a worthy exemplar.

Project Team

Client Newington Butts Developments

Structural engineer AKT II

Owner / funder Realstar Group

MEP Aecom

Contractor Mace

Cost consultant Arcadis

Planning consultant DP9

Development manager Mace

Concept architect Rogers Stirk Harbour + Partners

Delivery architect Axis

Placing the crown

Highpoint is topped by a distinctive four-limbed crown structure. The crown was Rogers Stirk Harbour + Partnersâ solution to resolving a planning and structural dilemma. The steel headpiece consists of four V-shaped arms, which cantilever out above the balconies on each corner of the tower. âSouthwarkâs planners were interested in how the tower met the sky so Rogers came up with the idea of the crown, which both satisfied the planners and was functional in that it helped dampen movement in the balconies,â says AKT II director Rob Partridge.

șĂÉ«ÏÈÉúTV the crown on top of the tower, 150m above the ground, was, literally, a balancing act because the prefabricated structure was only stable once all of the steel members were in place and the connecting Macalloy bars tensioned.

Mace was able to use the experience of its team, many of whom had been responsible for installing the spire on top of Londonâs Shard, to develop a safe installation methodology.

First the team modelled the assembly process digitally. Then they ran a full-scale trial assembly in a field in the West County, in partnership with steelwork contractor Bourne Steel, to test the methodology and ensure it had a safe system of working in place. The mock-up also enabled the team to check the structureâs actual movement in against the predicted movement during the tensioning operation. The ground-level mock-up even used the actual riggers who would later install the structure on top of the tower to ensure all were familiar with the challenge that lay ahead.

The trial was a huge success and the final site installation went without a hitch.

âIt was a big investment in both time and money, but it did highlight some issues and we did have to re-cut some holes, which would have been a disaster 150m up,â Guy Hunt, Mace project director says.

No comments yet