Getting the trains to run on time is one thing, but running to the timetable on a project the size of the £700m refurbishment of Birmingham New Street - while keeping the existing station fully operational - is something else entirely. Thomas Lane jumps on board

PROJECT TEAM

Client Network Rail Ltd

Project construction management Mace

Concept architect AZPA - Alejandro Zaera Polo Architecture

Executive architect Atkins

Structural engineer Atkins

M&E engineer Atkins

Facade engineer AKT11

QS Faithful & Gould

John Lewis ��ɫ����TV Architect Haskoll

M&E engineer Hoare Lea

In just over a week Birmingham’s rail users will be in for a pleasant surprise. Instead of disappearing into a dark and dingy subterranean black hole and in all probability getting lost between entrance and platform, they will walk into a shiny, brand new station. The first phase of the £700m refurbishment of Birmingham New Street completes on 28 April and passengers will be treated to a shining entrance of stainless steel cladding rather than drab old concrete, and a brand new station concourse complete with shops of course. New lifts and escalators will take passengers down onto the platforms.

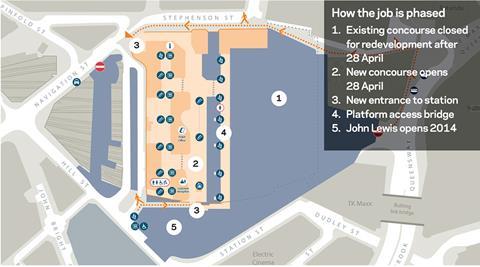

Although this will welcome, Brummies will have to wait until April 2015 to appreciate the full benefits of the multimillion-pound investment. The job is a game of two halves - the existing station will close as the new part opens and will be refurbished over the next two years into a much bigger and better station than the original. “The development will deliver three times more space at concourse level, a high-quality environment with lots of natural light, new pedestrian links through the station and stunning architecture, a station befitting the UK’s second largest city,” explains Chris Montgomery, project director for Network Rail. The job also includes transforming the down-at-heel Pallasades shopping centre over the station into an upmarket retail destination complete with a new John Lewis on the south side of the development.

This job is long overdue. New Street Station is the biggest rail interchange in the UK and the biggest station outside London. Up to 150,000 people use it each day with a train arriving or departing every 37 seconds. Another 50,000 people use the Pallasades, and there are 1,500 station staff, too - Birmingham’s central location means many train operating companies are headquartered here. All these people have to endure a depressing, sixties-built station designed to cope with just 65,000 people a day. There is no natural light in the station or at platform level, wayfinding is terrible and because there is no way over the tracks for one kilometre, a great swathe of the south side of the city is isolated and this has contributed to its decline.

Transforming this basket case has been a massive challenge. “Because it is operational with 200,000 people using it each day, it is a railway station and shopping centre first and a construction site second - we have to fit around these operations,” explains Montgomery. “Wembley stadium cost £700m and was closed for seven years. Our project costs the same and has to be done in five years and is open for matches every day.”

Keeping the station open has meant retaining the original structure. “In 22 years this has been one of the most challenging, technically difficult projects I have encountered,” says Richard Thorpe, contractor Mace’s project director. “It’s a postage stamp of a site, there is nowhere to put materials down, there are 150,000 people going through every day, plus people using the retail next door. It’s an old structure and the original workmanship wasn’t brilliant so the structure is very fragile.”

Because the platforms are below ground under the concourse, it is classified as an underground station which has made the job more complicated as all work is subject to onerous fire regulations.

A multi-storey car park on the western side of the station has been the key to unlocking this project. This has been transformed into the new passenger concourse complete with escalators down to the platforms while the existing station has operated unaffected. A temporary wall separates this work from the existing station and extends into the shopping centre above, neatly slicing the job in half.

The first job was to remove one level from this car park to create sufficient headroom for the new concourse and services. This was done by demolition specialist Coleman before the main contract commenced. The delicate nature of the structure called for an unusual demolition method. The level being taken out was directly over the slab separating the car park from the tracks below. This is just 140mm thick with the risk that demolition debris, if dropped, could crash through the slab onto the tracks.

The solution was to install a gantry crane running on rails attached to the columns. Chunks of 3m by 5m slab were cut out and transported out of the building using the gantry crane. Temporary trusses were installed under the beams so these could be cut into short sections and taken out with the crane. Using this method 7,500 tonnes of concrete were taken out.

Complexities

Mace started work in April 2011. “This isn’t one project but many projects bolted together,” says Thorpe explaining he has divided it up into 13 different jobs. Work areas include the M&E, platform improvements, the roof and the concourse works. In addition to the complexities of working on a live station and shopping centre, the contractor has had to cope with major design changes and all the unexpected problems thrown up by a refurbishment of this nature.

The biggest change was the need to redesign the job six months after Mace started work to accommodate a John Lewis store on the south side of the station. This had a major knock-on effect on the construction programme which still had to be completed within the same timescale. “Getting out of the ground was a massive, massive challenge,” says Thorpe’s colleague Paul Dalton who is the senior project manager for the retail areas. For a start there was a 25-storey residential tower on the site which had to be cleared of residents and demolished. This area is known as the “hinterland” and also included train operating companies’ accommodation, food preparation facilities and a welfare area for drivers. New accommodation had to be built for these organisations before work could start on the store.

Little was known about the structural condition of the station because, being occupied, only limited intrusive investigations could be carried out. This has tested the project team to the limit. A mezzanine area was to be refurbished as Network Rail offices but concrete cancer was discovered in the structure. “We discovered this was badly affected by chlorides so we’ve had to demolish the slabs and the affected areas of the beams,” sighs Thorpe. “That put a nine-month delay into a nine-month programme but we managed to do the whole job in nine months by working 24/7.”

He adds that the fitout phase was further complicated by the specialist contractor Swift Horsman going into administration just as they were about to start work. Thorpe switched to fitout contractor Elliot Thomas and got them to retain Swift Horsman’s employees to retain their skills and knowledge of the job. Thorpe has had to contend with four specialists going under on this job including concrete specialist John Doyle. Unusually he got steelwork specialist Watson Steel to take on the scope of John Doyle’s work.

The most extreme structural problem was a second multi-storey car park built over the western end of the station. No one anticipated the corrosion caused to the structure by salty water dripping off cars onto the unprotected slab during winter months. “It was cheaper to knock it down and rebuild it,” says Thorpe, a decision that added £20m to the bill.

Thorpe’s life is dominated by a computer screen covered in little graphs. Each graph has a line representing where a job package should be according to the programme, and another line plotting the reality on site. The two lines are a long way apart on many of those graphs, representing delays out on site. Thorpe’s life is spent thinking up ways of getting those two lines to converge again.

He has two key strategies to cope with this challenge. The first is to do everything as efficiently as possible. Mace and Network Rail have worked hard to train up workers to look at problems in the same way so they appreciate how each team impacts on the other. The idea is that a collaborative approach gets the job done more efficiently. This strategy has also been used to get workers to understand the impact of their work on rail and shopping centre users to minimise disruption.

This approach has been applied to the platform refurbishment. This is a critical part of the programme as the station operates at 90% capacity which means only one platform can be taken out of action at a time. Work includes new drainage under the platforms, new services and platform surfaces. Thorpe says the platforms were being refurbished in an inconsistent manner which meant the work was taking longer than programmed. The new strategy is paying off: the first platform took 26 weeks to refurbish, but the team have now got this down to just 12 weeks.

The second strategy is to come up with smarter ways of achieving the same objective. Originally new services were going to be threaded through the building. Two vertical spines have subsequently been identified as service risers which simplifies the task. M&E specialist NG Bailey has supplied and installed the western service spine as modular units, speeding up the job.

A big time saving was found for platform level ventilation. The original plan was to replace the ductwork running from the platforms up to plant on the roof of the station. “It was almost impossible, hugely inefficient and costly,” says Thorpe. The answer is impulse fans which are used to ventilate tunnels and eliminate the need for ductwork. These are mounted above the platforms along its length and work by pulling clean air at one, open end of the platform and expelling it out of the other.

Despite these solutions, the first phase is opening four months later than planned. “Given the problems we have had with the structure, we have held our own fairly well,” says Montgomery. The second phase is complicated by the need to provide platform to concourse access along the length of the platforms due to fire regulations. The existing bridge sits just the other side of the new concourse and will continue to be used by passengers. Mace will construct a modular tunnel over 10 nights that will allow passengers to access the platforms and allow construction work to continue overhead. Escalators will be installed 25m to the east of this tunnel and once these are finished the whole tunnel will be moved adjacent to these escalators, maintaining passenger access and allowing Mace to work in the area previously occupied by the tunnel.

Another big job is creating the atrium that will bring light down onto the concourse. This cuts through two levels of the shopping centre with a total area equivalent to a football pitch. The bulk of this atrium will need to be cut into the structure of phase two as only 15m of atrium intrudes into the first phase. The ETFE roof used for the atrium will also be built during this phase.

Time lost during the first phase will have to be made up during this second phase.

The key strategy is to continue with the collaborative approach and apply the lessons learnt on the first phase to work on the second.

Montgomery is optimistic that the station will be finished in time for the original April 2015 deadline although he concedes the platform work could drag on into June. “We will inevitably find problems, but this time we will have ready-made solutions,” he says. In the grander scheme of things a month or two doesn’t really matter - the station is at the heart of the city and with half of the visitors to Birmingham arriving at New Street this refurbishment could rehabilitate the city’s grimy, grey car-dominated image.

THE PROCUREMENT STRATEGY

The upgrading of Birmingham New Street has been procured via an unusual route as Network Rail has put just £50m into the £700m job - £600m is the construction value. The bulk of the money has come from Advantage West Midlands, the Department of Transport, the council and Centro. The procurement model for the work is very similar to the relationship between the Olympic Delivery Authority and CLM during the London Olympics in that Network Rail is delivering the project on behalf of the funders and Mace is working with Network Rail as the delivery partner. The two organisations work out of one office with Network Rail staff embedded in the Mace team and vice versa to benefit from each other’s experience.

The job is similar to construction management in that Mace and Network Rail procure works packages directly with suppliers. A suite of Network Rail contracts is used for procuring those packages ranging from lump sum to NEC-type pain and gain sharing contracts. Both parties are convinced this was the right approach. “It brought more construction and buildability into the design phase and brought in an extended supply chain,” says Montgomery. “It also enabled us to break the job down into smaller packages and manage those interfaces.”

Thorpe is more direct about the advantage of this form of procurement. “If this had been let as a lump sum contract for £600m, it would have gone £300m over budget just like that.”

THE DESIGN STRATEGY

The idea behind the New Street development is to create an iconic landmark for the city which is much easier for people to use. The station has been designed by Foreign Office Architects, now known as Alejandro Zaera-Polo Architecture. The drab concrete sixties structure is being encased in panels of shiny stainless steel that swoop and curve around the building. This incorporates large digital displays to help people find the entrances.

Inside will be an atrium that will flood the enlarged passenger concourse with natural light. This is being created by punching through the two retail floors over the station and topping this with an ETFE roof. The shopping centre will be refurbished to make it a retail destination, an ambition helped by the arrival of the first John Lewis store in Birmingham.

Inside, passengers will enjoy a concourse three times larger than the original. This has been modelled on an airport - passengers are held back in the concourse and go down to the platforms just before boarding, which makes sense given the subterranean platforms. Access to the platforms for the station’s 50,000 passengers a day will be eased as there will be 28 escalators rather than the current five with 15 lifts rather than just nine. Ultimately it will be able to handle an expected 250,000 passengers a day by 2035 once train throughput has been increased by improving the signalling to the station.

The wider city will benefit as the development incorporates links between the north and south side of the station. The rundown south side of the station will be further boosted by the John Lewis store - according to Montgomery, property prices are already on the rise in this area.

No comments yet