As part of our report into how architects approach product specification, we interviewed Cullinan Studio partner Colin Rice, for whom circular economy principles are a key interest

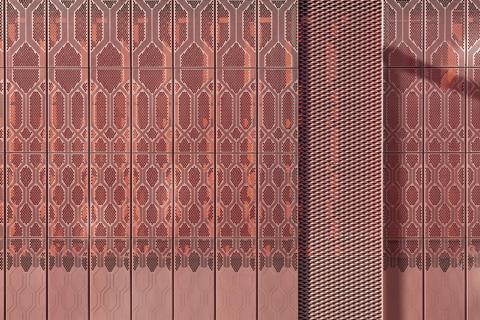

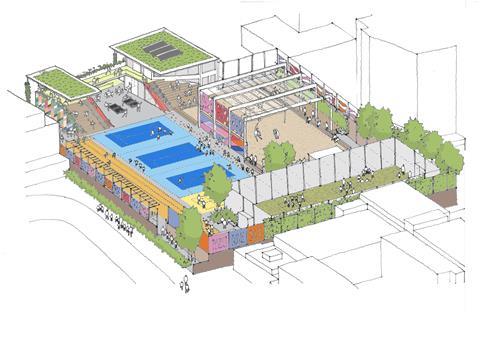

A sustainable philosophy of connecting people and nature has always been at the heart of Cullinan Studio’s work and is exemplified in projects like the recent Bunhill 2 Energy Centre in north London, which is reusing waste heat from London Underground tunnels to warm homes and other buildings.

When it comes to specification, partner Colin Rice says the practice has recently changed the way it works, bringing in some outside consultancy support on specification-writing to sit alongside its use of the NBS Chorus tool. The move is designed to help give a more co-ordinated approach, partly to enable better integration with Revit, for BIM.

What are the issues currently impacting on specification – and how are these changing?

There are two main drivers for rapid change. The first is the climate crisis and our need to work with, persuade and help clients to deliver net zero carbon buildings. A subset of that is working with existing buildings.

The second driver is around the consequences from the Grenfell Tower fire and the need to have the so-called “golden thread” of information, with specification data being part of the information about an asset.

Are any design trends having an impact – if so, what?

They are related to the drivers. We have a new job where it is part of the client’s brief to try and work to circular economy principles. That’s something I’ve personally been interested in for an awfully long time, and I did a small project where I followed that as far as I could.

But in a more significant project, how does that work in practice? We’re doing the obvious things like talking to Cleveland Steel to look at reusing steel from its supplies, and to a supplier of second-hand timber in Essex about using greenheart piles as material for the roof structure.

That in turn raises the bigger question of whether we start with the materials and design around what’s available, or do what we’ve traditionally done and design more in abstract and then specify the materials to deliver it.

Generally, if we’re going to work to circular economy principles, we’ll have to have a keener ear to the ground about what’s available. The idea of material passports is a good one.

How are you responding to these specification challenges?

Around climate change more broadly, we’re doing what we’ve wanted to do but probably a bit more rigorously, using natural materials and using materials with lower embodied carbon. To do that you need good information about the products or materials; you need to have the environmental product declarations (EPDs). There are a lot more around now.

On fire, it is really difficult. We have a long tradition of using timber in our buildings and would like to use more, because it is a more sustainable material than steel or concrete. We are working on a low-rise housing scheme where, as a condition of its funding, we can’t use any combustible materials in the external wall, which goes beyond ��ɫ����TV Regulations. That prevents us from using timber in the construction and closes down an option we should be looking at.

Where do you turn for information on product specification issues?

We use a mixture of sources, including NBS Source and the BRE Green Guide to Specification, and do quite a bit of Googling.

We rely on a network of sustainable sources, including the Alliance for Sustainable ��ɫ����TV Products, and firms like Mike Wye, which is a sustainable product supplier with good technical advice.

The old way of getting a company sales rep to come into the office to tell you about their product, and then largely relying on their word, has gone

For projects in low-rise housing, where we are working to the Passivhaus standard, it is easier to use certified products to complete the Passive House Planning Package.

How confident are you in these sources of information?

I think we’re less confident than we used to be, so we would check things more carefully now. The old way of getting a company sales rep to come into the office to tell you about their product, and then largely relying on their word, has gone.

Now we look for third-party accreditation, like British Board of Agrément or similar, but being more careful to check the fine print.

What are the issues or topics where specification knowledge is lacking?

It’s the areas where products don’t have EPDs.

For example, we’re looking at improving the acoustics of the canal level of our studio. Ten years ago, when we moved into the building, we added acoustic insulation to the top floor, which was partially made from recycled PET. Now we’re trying to reduce plastic so we’re looking at a Somerset sheep’s wool-based product. But they don’t yet have an EPD.

The ideal to meet the regime that we have now would be to have low embodied carbon materials that are non-combustible, but that’s not likely

What do you think would help improve knowledge on challenging specification issues – and how could manufacturers help?

The new Construction Products Association Code for Construction Product Information looks to have a good aim, in trying to put information in a way that is clear, unambiguous and allows for comparison.

There is scope for second-hand materials suppliers to promote their materials in the same way.

What product developments would you like to see to ease some of these challenges?

The ideal to meet the regime that we have now would be to have low embodied carbon materials that are non-combustible, but that’s not likely.

What we also need is a more realistic regulatory environment on how you manage risk in design, rather than the present blanket approach of saying you can or can’t use a material.

Intelligence from architects: Product specification report

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

Currently reading

Currently readingInterview: Colin Rice, Cullinan Studio

- 10

- 11

No comments yet